2+1 years

Easy warranty registration

All Mirka power tools have a standard two-year warranty. Get an additional 1 year of warranty free of charge by registering your tool within 30 days of purchase.

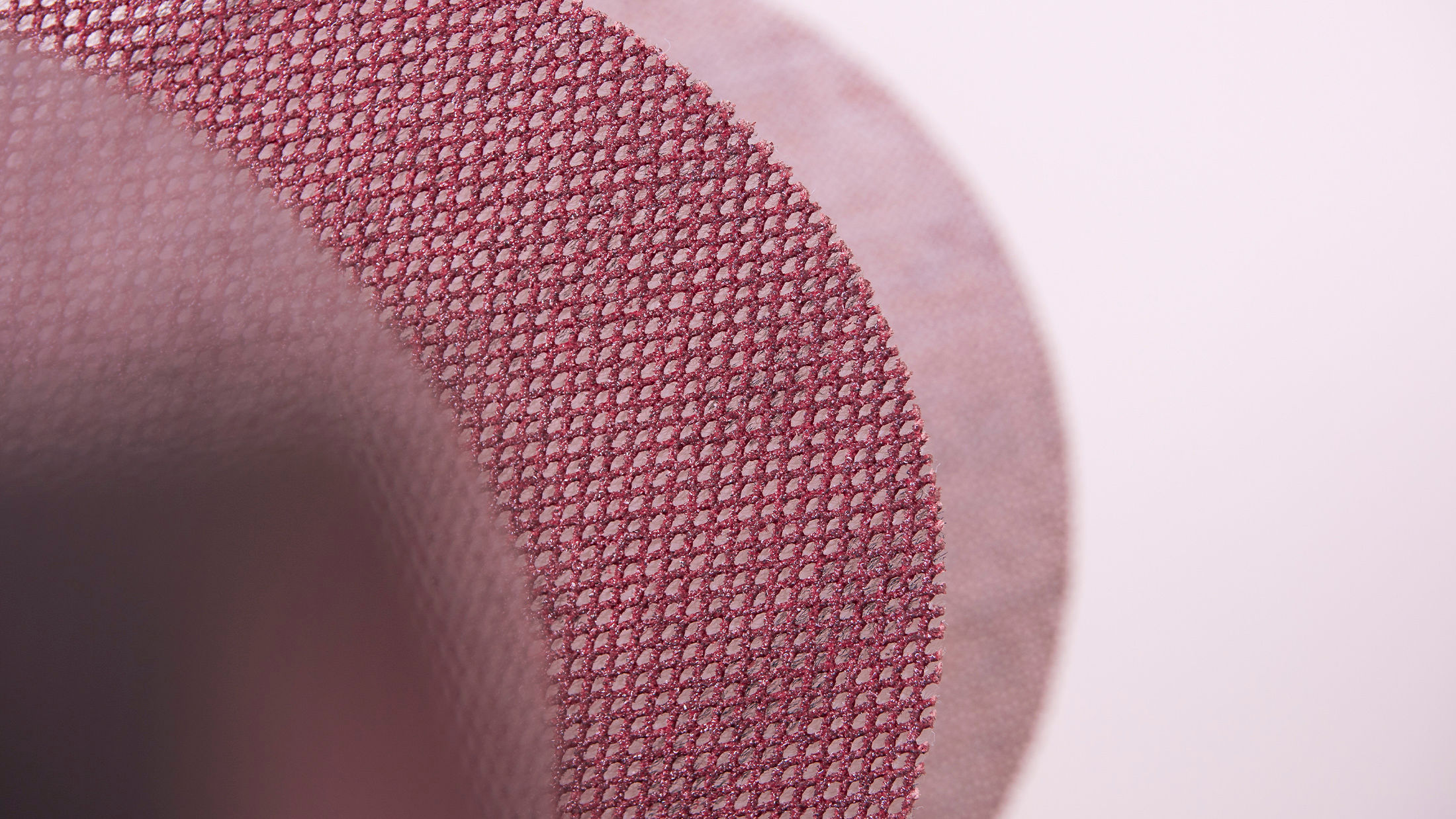

Abranet is highly resistant to dust, which helps ensure optimal usage for all types of sanding work. When combined with our ergonomic and efficient power tools and dust extractors, you’re guaranteed a dust-free surface, every time. Abranet is multifunctional, perfect for sanding fillers, primers, topcoats, composite materials, and a wide range of other materials for industrial applications.

When sanding, you can bet there will be dust, and this is something to take seriously. Dealing with dust can be expensive, time-consuming, and dangerous. By using on-tool dust extraction, dust can be safely removed from the working surface without it ending up in the air, on the floor, on your skin, and in your lungs.

To put it simply, Abranet helps increase profits. Adding Abranet to your arsenal, you’ll never see a better quality of finish in your work, all while helping protect your health.

When money and health are the two things that we all aspire for, it’s an easy decision when choosing an abrasive, choose Abranet.

Twenty years ago, Mirka first introduced Abranet. We solve your problem by providing you with a complete dust-free solution for your sanding challenge. Read more about Abranet®.

The most dangerous dust is so-called invisible dust that can stay airborne for a long time, building up in the lungs. It has already been in the air long before it settles down on the surfaces.

Paint residue can be highly toxic and dust from hardwood is extremely harmful if inhaled for long periods of time.

This is why, even though we created the best abrasive for a dust extraction tool, we still recommend wearing protective gear.

Want to know more?

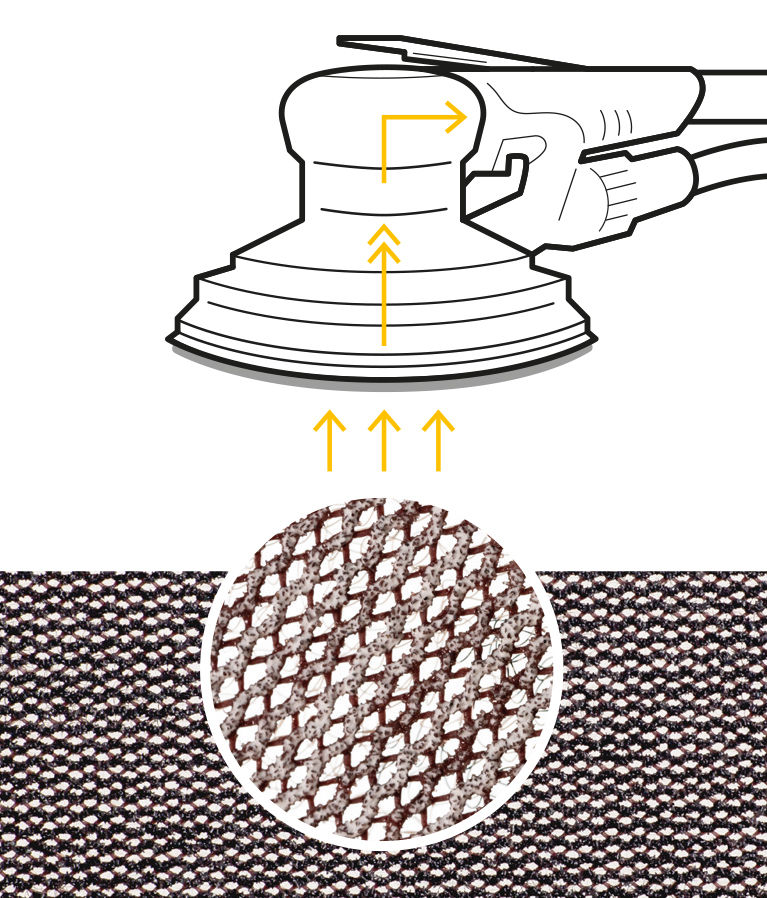

Abranet will attach to your backing pad and its thousands of holes help provide the best dust extraction in the market. The maximum distance from each sanding particle to the closest dust extraction hole is just 0.5mm.

The cleanup after sanding does not have to be a chore anymore. Our net abrasives are just perfect for highly efficient dust extraction.

Check out Abranet and explore its possibilities from our variety of dust extractors.

Trust Mirka with the most integral part of your work. We only believe in providing the best, for the best.

See below what our customers say about Mirka's dust-free sanding.

Salvi Harps, Italy

True dedication is something that is hard to define as it means different things for different people. For Enzo Vizzone of Salvi Harps, it means creating uniquely finished instruments and helping the beautiful harp music travel around the world.

"For us, the finishing process is the most important one."

Decorative Painter, France

Having the right tools for the right sanding application is crucial if you want to exceed expectations in the finish, whether you work on something new or doing renovation work. For Alexandre Lardy, plasterer and decorative painter from France, choosing a dust-free solution from Mirka was an easy choice.

"One thing I’ve really liked and that struck me immediately is the dust extraction aspect.

I have the impression that I’m not sanding at all, so effective is the extraction – I get absolutely no dust."

Fix Auto, USA

A cleaner shop means healthier employees and a better working place. Marc Milot, Manager at Fix Auto appreciates how their body shops are now dust-free.

"By far one of the best investments we've done. We've been able to cut our abrasive costs. They last a little bit longer. The vacuum systems work great. Overall, everybody is really excited and happy that they don't have to be full of dust every day."

Toyota St Therese and CarrXpert St Julie, CANADA

David Saint-Laurent from CarrXpert St-Julie explains how switching to Mirka has increased performance, kept the shop clean and created a better finish.

"Now, we don't have to have 15 or 20 grits, we are working with only 4 grits."

Original patented net abrasive

Multifunctional, developed for sanding fillers, primers, lacquers, composite materials and a wide range of other materials for industrial use.

Available in discs, strips, triangles, rolls.

Ceramic grit on ultra-fine mesh

Achieve outstanding results across challenging surface conditions, on hardwoods and solid surfaces, and for priming and repair applications.

Available in discs and strips.

Ceramic grit on reinforced mesh

Durable and tough, ideal for heavy-duty applications, stripping and hard surfaces.

Available in discs, strips, triangles, rolls.

First patented net belt

Universal. Suited to a broad variety of belt sanding applications. Especially developed for the wood industry.

Available in portable belts.

Net abrasive for automotive repair

Net abrasive range specially designed for Mirka's Optimized Surface Preparation System for collision repairs.

Available in discs, strips, rolls marked with numbers

Get Your Free Copy of Our Whitepaper

In this whitepaper, we consider the hazards associated with the task of sanding and the harm that can result from prolonged exposure to those hazards.

We go into the deep and explore: