2+1 years

Register Your Tool

All Mirka power tools have a standard two-year warranty. Get an additional 1 year of warranty free of charge by registering your tool within 30 days of purchase.

At Mirka, we believe there is always a better way. The result is a thoughtful approach to innovation that does not just drive product development, but everything we do. We have never stopped improving our products and brand.

The heart of Mirka’s operations are our Values; To be Responsible, Committed, Innovative and Respectful, our Vision; To be the responsible market shaper that inspires renewal and leads with innovation, and our Mission; To give people the opportunity to perform better.

All these three are epitomized in our slogan, “Dedicated to the finish”. This is a promise, which means that we are fully engaged in all details of a solution. We are in constant motion and we strive for a better way. It all starts with the question; “What is your challenge?”

With our knowledge and expertise, we find the right combination of abrasives, tools, and polish for a specific purpose, but we also identify the customer’s needs. We form a relationship with the customer and work in collaboration with them on every aspect, to understand and address the whole picture and give them the solution to reach that perfect end-result.

We are the sustainable industry shaper in the surface finishing business and a leader within all segments in our market. Leadership means that, through insights and proactivity, we offer customers high-quality systems, tools, and services. We do not only deal with isolated, short-term solutions, but work constantly to achieve sustainable long-term improvements across the entire industry and process – technically, economically, environmentally and in terms of working conditions.

Our trigger is and has always been "how hard can it be?"

This has made us the global market leader we are today – a leader who is down to earth and looks beyond the “impossible”.

Since 1943

Mirka's history started almost 80 years ago in Ostrobothnia, Finland. Since then, we have been dedicated to the finish.

Efficient and ergonomic

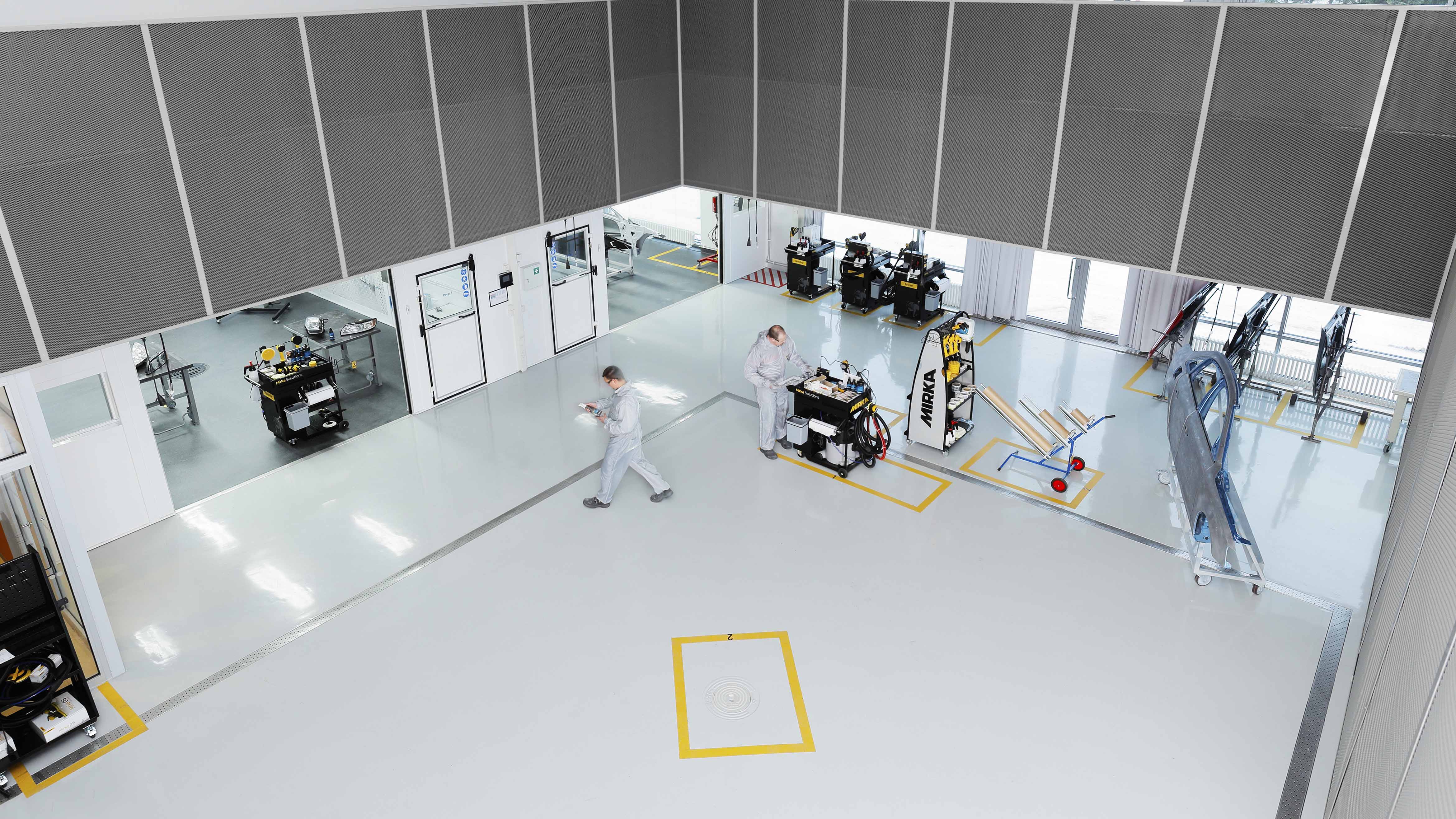

We are dedicated to give you the opportunity to perform better. With our award-winning and popular Mirka power tools, you can be sure you get the best sanding and polishing results.

Want to know to peek behind the scenes and meet the Research & Development team that gave us sanders like Mirka® CEROS, DEROS, and LEROS, that revolutionized sanding in workplaces all around the world? Click the link below.