2+1 years

Register Your Tool

All Mirka power tools have a standard two-year warranty. Get an additional 1 year of warranty free of charge by registering your tool within 30 days of purchase.

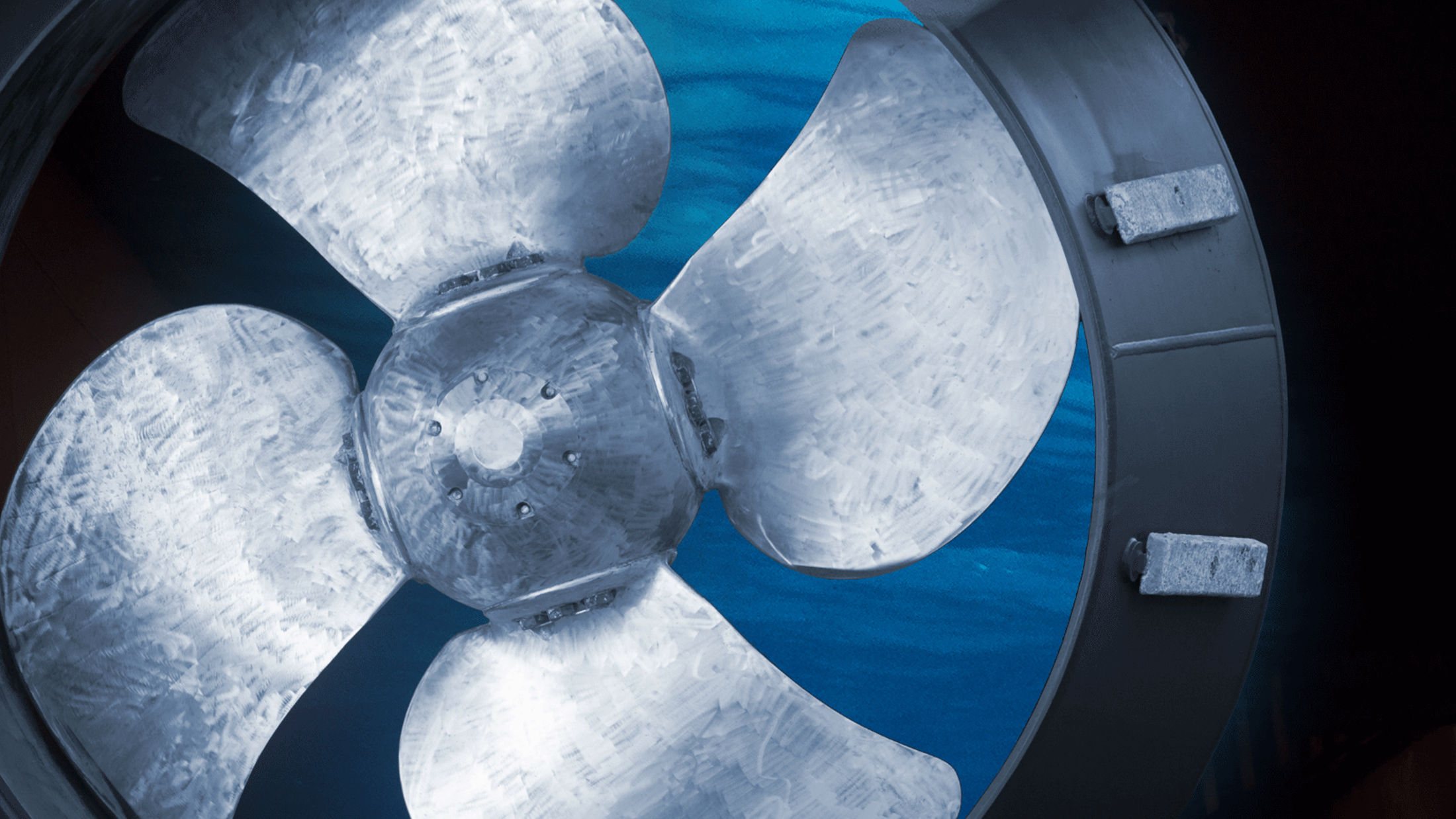

Automated propeller manufacturing

The systems are suitable for everything from cast mold machining to surface finishing and polishing. Most of the manual work can be automated, which results in reduced manufacturing costs and lead times while achieving better and constant quality. When manual processes are automated, working conditions are dramatically improved while also securing production capacity.

Different configurations are available for controllable pitch propellers (CPP), fixed pitch propellers (FPP), impellers, etc..

Advanced force-controlled robotics

Mirka's robot system can utilize the grinding and polishing tools for the surface finishing and the milling tool for finishing edge contours and areas used for connecting a part from a potential previous process step to the milling machine.

With force control, the tools will accurately follow the surface for the best results. The system consists of one large payload force-controlled robot system and a high-precision rotary servo table. The finishing process is completed by utilizing the Electrical Spindle Motor mounted on the active force compliance unit and a variety of different grinding disks and stones.

Measuring

Best-fit operation with CAD model

Programming with CAD/CAM

Controlled grinding- Adaptive material removal based on measured information

Milling of edge contour

Finishing

The robotized platform is well-suited for machining all kinds of pattern materials such as expanded polystyrene, high-density structural foams, tooling paste, wood etc. The typical process equipment used for pattern machining in the robot system includes:

Instead of using patterns, molds can be machined directly to the sand. This will increase the flexibility in production.

The following equipment is typically utilized in the Flexmill robot system for direct mold milling: