1 Extra Year

Register Your Tool

Get an additional 1 year of warranty free of charge by registering your tool within 30 days of purchase.

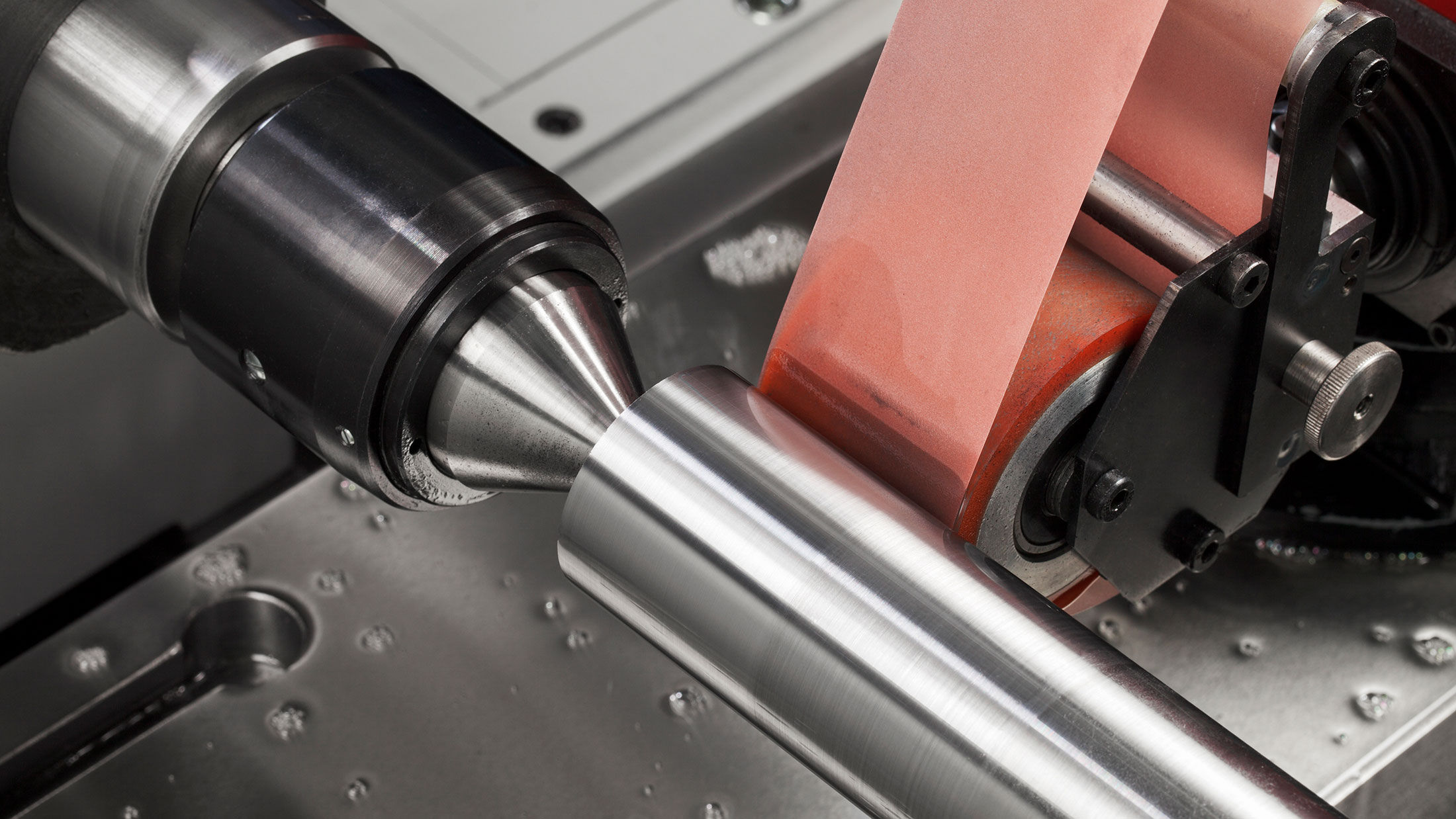

Consistent OD results with short grinding times

Optimised wheel dressing time

Peace of mind through security

Mirka’s abrasive films are what you need to achieve consistent functional surface values in your superfinishing or polishing operation. Featuring an anti-slip dot pattern on the back, we offer two different film products to help you easily select the right product for your specific polishing needs