1 Extra Year

Register Your Tool

Get an additional 1 year of warranty free of charge by registering your tool within 30 days of purchase.

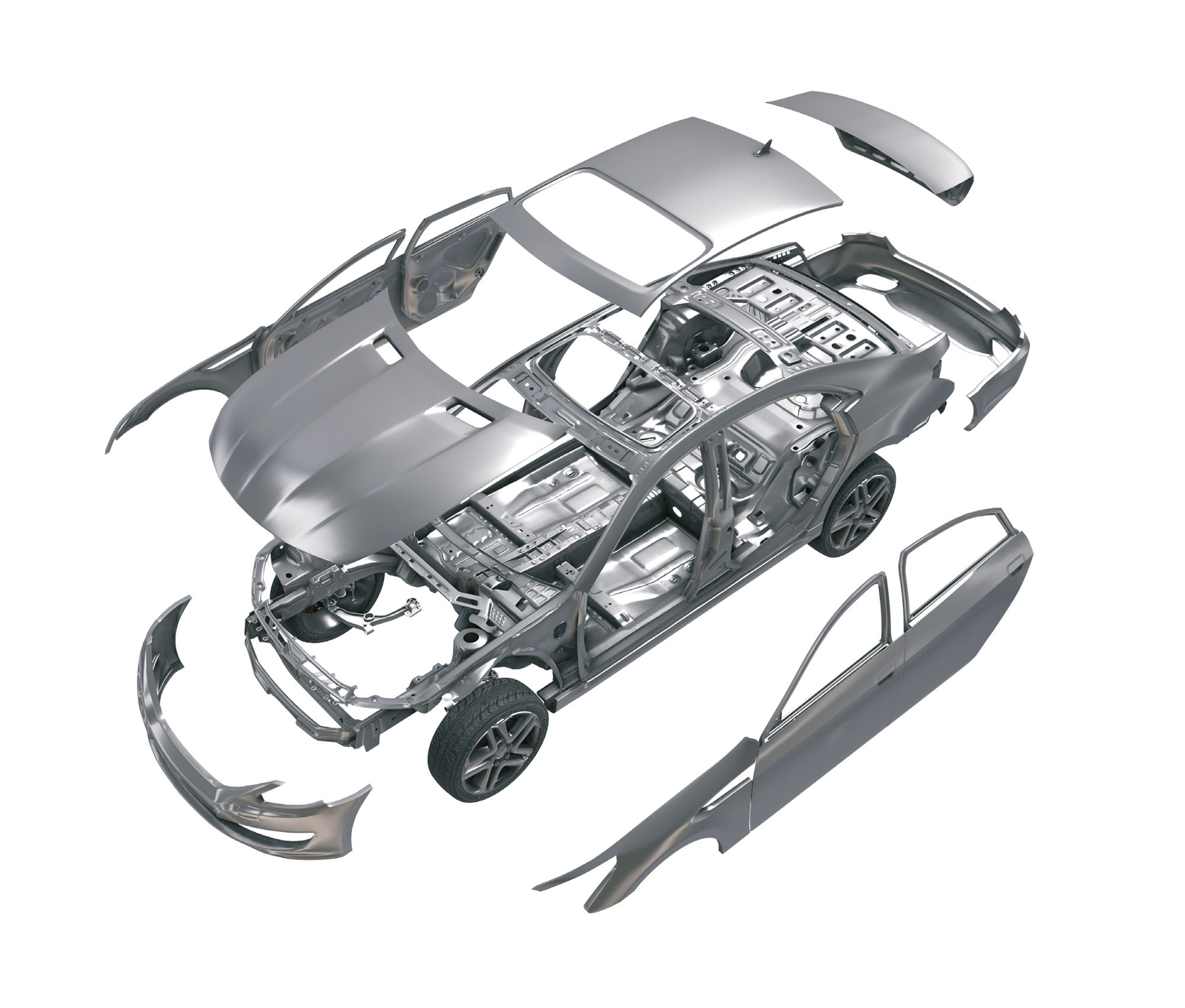

From removing defects to perfecting the finish

Tier 1 suppliers manufacture parts for automotive and transport OEMs, which means the quality of the supplied body parts must match the quality and surface perfection of the complete vehicle. Mirka provides many different sanding solutions for sanding plastic, fiber reinforced plastic and other composite parts, from abrasives to tools, for removing any defects or flaws from the molding process.

Automotive parts from Tier 1 suppliers

Prepare the surface after molding process

The molding process of a plastic or composite part can leave behind defects such as flash, fiber risings or parting lines. Choose Mirka Abranet, Abralon or Goldflex Soft for machine sanding or hand sanding the unpainted surface smooth. After the bare finish has been perfected, the part is ready for layers of paint.

For machine sanding, Mirka DEROS or ROS power tools give you an ergonomic working process that is dust free, for a cleaner working environment and reduced need for re-works.

Post-paint spot repair and finishing

Remove defects in seconds from paint or clearcoat using Iridium SR spot repair abrasives and handy cordless tools. Dust nib removal is quick and ergonomic work thanks to efficient cordless tools, which give a consistent finish in sanding and polishing.

The scratch pattern of the Iridium SR makes sanding marks especially easy to polish using our water-based polishing compounds.

Complete solution for spot sanding and polishing

Mirka's innovative tools and abrasives combined with the newly released Mirka PRO Iridium™ 1250 polishing compound make for a simple, fast, and reliable system for a high-quality surface finish in manufacturing plastic and composite body parts.

The water-based Mirka PRO Iridium™ 1250 compound is the final piece of the puzzle in the finishing solution. With the PRO Iridium™ 1250, you only need to polish once.