1 Extra Year

Register Your Tool

Get an additional 1 year of warranty free of charge by registering your tool within 30 days of purchase.

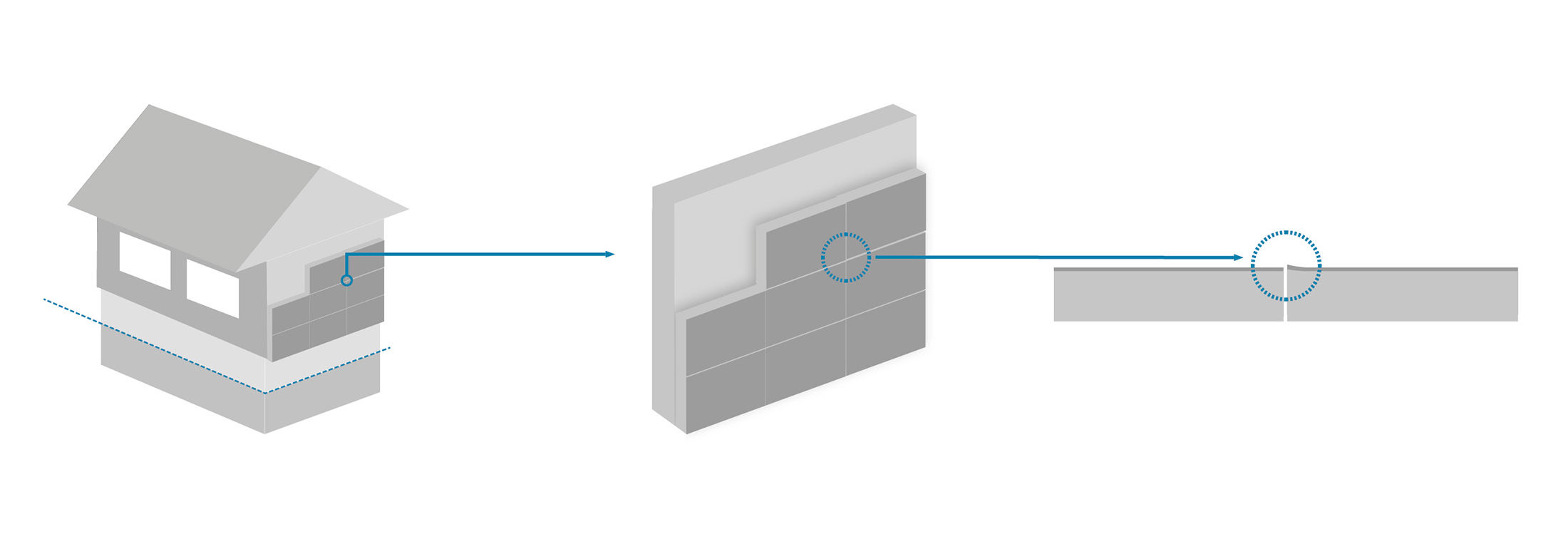

To save energy, buildings can be fitted with extra insulation panels, either underground, on the plinth, or on the exterior wall of the house. This helps to improve the containment of heat, as less heating energy is wasted.

Fitting insulation panels requires trimming them to correct size and leveling the panels so they can be painted and decorated. Without sanding the panels, the edges will stand out and make the building look unfinished, or make applying paint difficult.

Easy, Clean and Fast

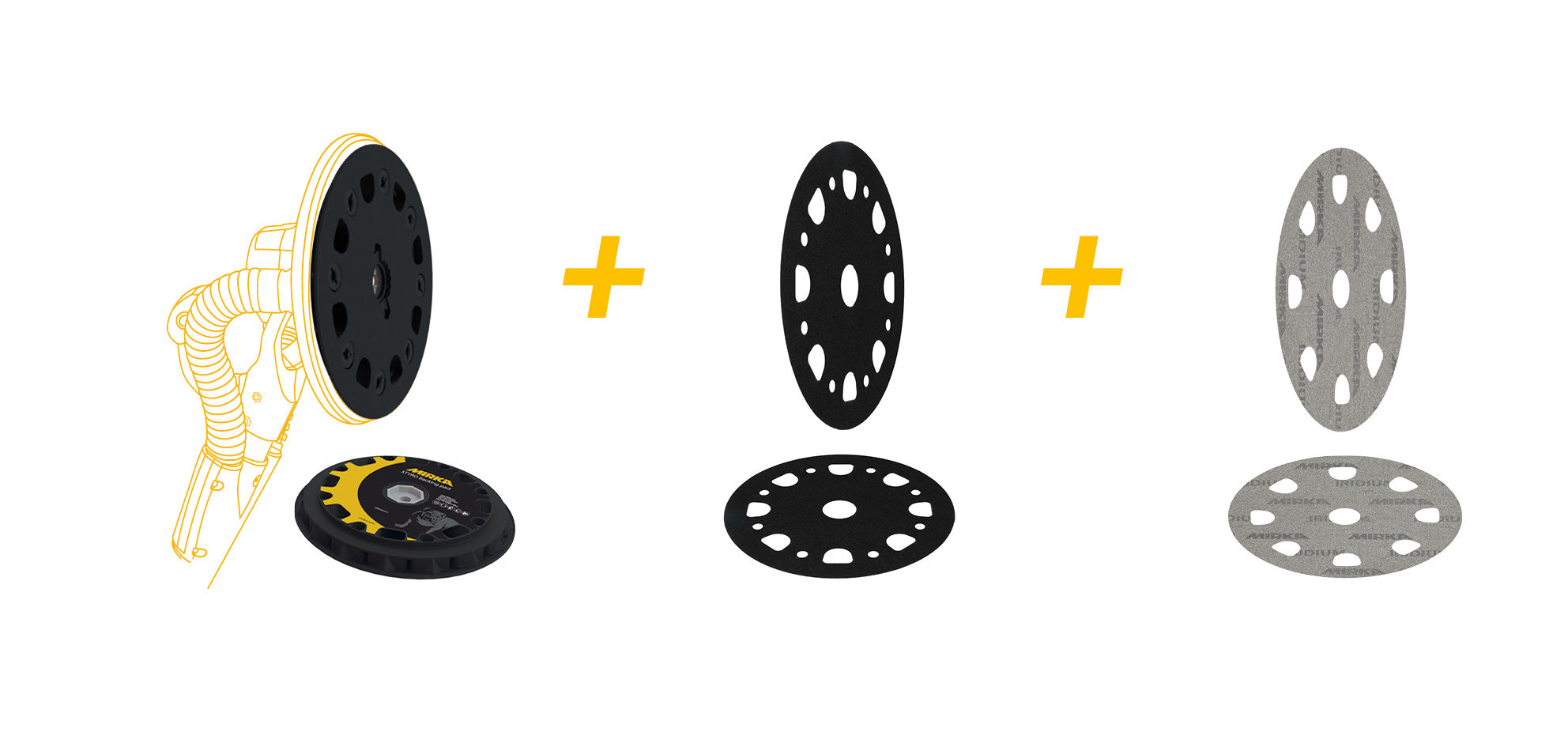

With the help of Mirka’s new STYRO Concept, fitting polystyrene insulation could not be cleaner. Usually, when leveling panel seams to achieve a uniform structure, debris is created from sanding insulation foam. To solve this, Mirka’s ergonomic and easy to use LEROS-S wall sanders are fitted with a special backing pad and Mirka STYRO abrasives together with an interface to make sanding work easy, clean and fast.

Suitable for XPS and EPS polystyrene

The system is suitable for sanding underground and external insulation panels alike, for Extruded Polystyrene (XPS) and Expanded Polystyrene (EPS). With the specially developed Mirka Iridium abrasives for the STYRO Concept, debris extraction capability is improved even further. Mirka offers different grits to suit different density of polystyrene, from P40 to P80.

Reduce strain and speed up your work

Mirka’s LEROS-S wall sander is designed to reduce strain on the operator, helping you to make quick work of the job at hand. Thanks to efficient abrasives and powerful dust extraction, you can minimize both the time needed for the sanding process and the amount of debris from sanding foam.

The combination of ergonomic sander design and dust-free sanding reduces discomfort as well as the risk of occupational disease, especially in tackling large areas such as wall insulation.

What is the Mirka STYRO Concept?

Which abrasives are included in the STYRO Concept?

The STYRO Concept features Mirka’s Iridium abrasives, developed specially for the concept with larger dust extraction holes.

Do I need to use an interface?

An interface is an essential part of sanding insulation to make sure the panels are completely level. The interfaces and backing pads in the STYRO Concept are developed to direct large debris created from sanding polystyrene.

What is the difference between insulation panel materials?

The Mirka STYRO is suitable for sanding both extruded and expanded polystyrene. Extruded, or XPS polystyrene is denser, and expanded, or EPS polystyrene is more lightweight, with the choice of panel depending of its purpose and whether it is fitted underground or externally. Choose the correct grit of abrasive to make sure the sanding process is optimized.

How to select the right abrasive?

For sanding dense extruded polystyrene (XPS), we recommend grit P40. For an all-round grit, for medium density EPS insulation on the plinth, choose grit P60. When sanding wall insulation made from light density EPS insulation, choose grit P80.

What is the benefit of using a Mirka LEROS-S sander?

The Mirka LEROS-S is designed for sanding large surfaces with a secure grip and a large pad. It is easy and light to use in the sanding process, making work quicker and leaving a better finishing quality at the same time. It is compatible with Mirka’s dust-free sanding solutions that are an important part of the STYRO concept.

Do you want to know more?

Please get in touch and our expert support team will answer your questions.

Sand and polish safely without strain – Our tools and abrasives are ergonomic, efficient, and easy to use

Improve the quality of work – The finish is excellent, with less effort

Save time and money – You can cut costs and reduce working hours