2+1 years

Easy warranty registration

All Mirka power tools have a standard two-year warranty. Get an additional 1 year of warranty free of charge by registering your tool within 30 days of purchase.

Keep your tools in excellent shape on myMirka where you can register, manage and order repair for your tools.

Replenish your stock, access marketing materials, view sales guides and read about upcoming product launches.

The battery pack and charger included with the tool purchase are covered by the 2+1 year warranty program. The warranty does not cover parts bought separately.

When the battery is past its useable life, dispose of it according to your local laws and regulations.

Random orbital sanders are designed to be used with specific sized pads, with a precise weight. Make sure you are using the correct size pad, and that it is in good condition. Changing your backing pad when necessary will keep the vibrations of your sander to the minimum. Large chunks of missing pad

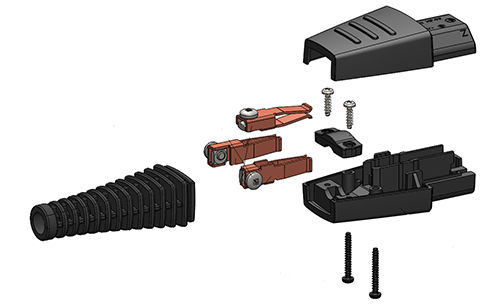

Over time, the cables on Mirka DEROS, DEOS and LEROS tools might break due to wear and tear. To address this matter, Mirka shifted from molded cables to cables with rewireable connectors on these tools. This means the cable connectors can be changed by the user themselves, without need for special t

If you experience the pneumatic sander gradually feeling slower, add 1-2 drops of oil into the air inlet and keep the machine running for 30 seconds so that excess oil is drained. The tool requires proper lubrication to prevent premature wear - keep it well oiled and it will continue to perform well

The DEROS Random Orbital Sander has not been designed for polishing. For polishing work, we recommend the following tools: Battery powered polishing tools AROP-B 312NV 3" ARP-B 300NV 3" Pneumatic polishing tools ROP2 312NV 3" ROP2 512NV 5" RPS 300CV 3" AP 300NV 3"

An interface is not included with the Mirka DEOS Delta 663 but can be purchased separately. The 7 mm thick interface is designed to make it easier to sand rounded and contoured surfaces and for some users it will add extra comfort while working. The interface is available in single packs and 5-packs

Mirka does not recommend using Mirka LEROS for hardwood floor or deck sanding, as it has not been designed for these particular applications.

It is likely that air is bypassing the vanes in the motor. This can happen if one or several motor vanes are stuck in place. If the compressed air is contaminated with dirt or water, it can cause a sticky residue to form and this can cause the vanes to stick. While it is important to keep your tool

Water will build up in an air compressor during use. A "dryer", or an in-line water separation filter should be used to prevent moisture from reaching the tool components.

If you experience the pneumatic sander gradually feeling slower, add 1-2 drops of oil into the air inlet and keep the machine running for 30 seconds so that excess oil is drained. The tool requires proper lubrication to prevent premature wear - keep it well oiled and it will continue to perform well

First of all, check and make sure there are no air leaks in the line, and that your compressor is producing 17 CFM at 90 PSI, the recommended pressure. If the air supply is adequate, check that the pneumatic tool is properly lubricated - it needs to be oiled to perform best. When the tool is noticed

The serial number location on Mirka power tools varies depending of the tool in question. Here you can find answers for finding the number on several of our tools. Click the following links to view an instructional PDF file. Mirka® AOS Angle Orbital Sander The serial number is located on the front o

Product information and technical specifications for Mirka tools, including machine manuals, exploded views, spare parts, related products etc. are available on the Mirka website and can be accessed through the following links: Electric orbital sanders (DEOS) Electric random orbital sanders (DEROS,

Yes, a wrench is supplied for changing the back-up pad. You can find it in the original packaging of the sander.

The model 1025 is not self cleaning. The 1230 dust extractor has a self cleaning mechanism which cleans the filter automatically every 15 seconds. The self-cleaning action is noticeable from a "thump" sound.