Register Your Tool

All Mirka power tools have a standard two-year warranty. Get an additional 1 year of warranty free of charge by registering your tool within 30 days of purchase.

Keep your tools in excellent shape on myMirka where you can register your tools.

Replenish your stock, access marketing materials, view sales guides and read about upcoming product launches.

Sport climbing made its Olympic debut at the Tokyo Olympics in Japan in 2020. Founded on agility, technique and self-orientation, the sport requires pieces of equipment called volumes, which are fastened to the climbing wall. These structurally robust, smooth pyramid-shaped wooden holds are made from short grain Birch plywood, which doesn’t splinter, and fixes the screws securely in place on the wall so there is no bad exit if the screws come out.

One company that is a leader in the manufacture of climbing walls is Rockcity based in Hull. The original Rockcity was established in 1994 as one of the UK’s first community indoor climbing facilities. It then added an indoor skatepark and has continued to innovate and develop its state-of-the-art facilities to encompass a collection of ideas and different companies spanning climbing, skate, BMX, and community facilities.

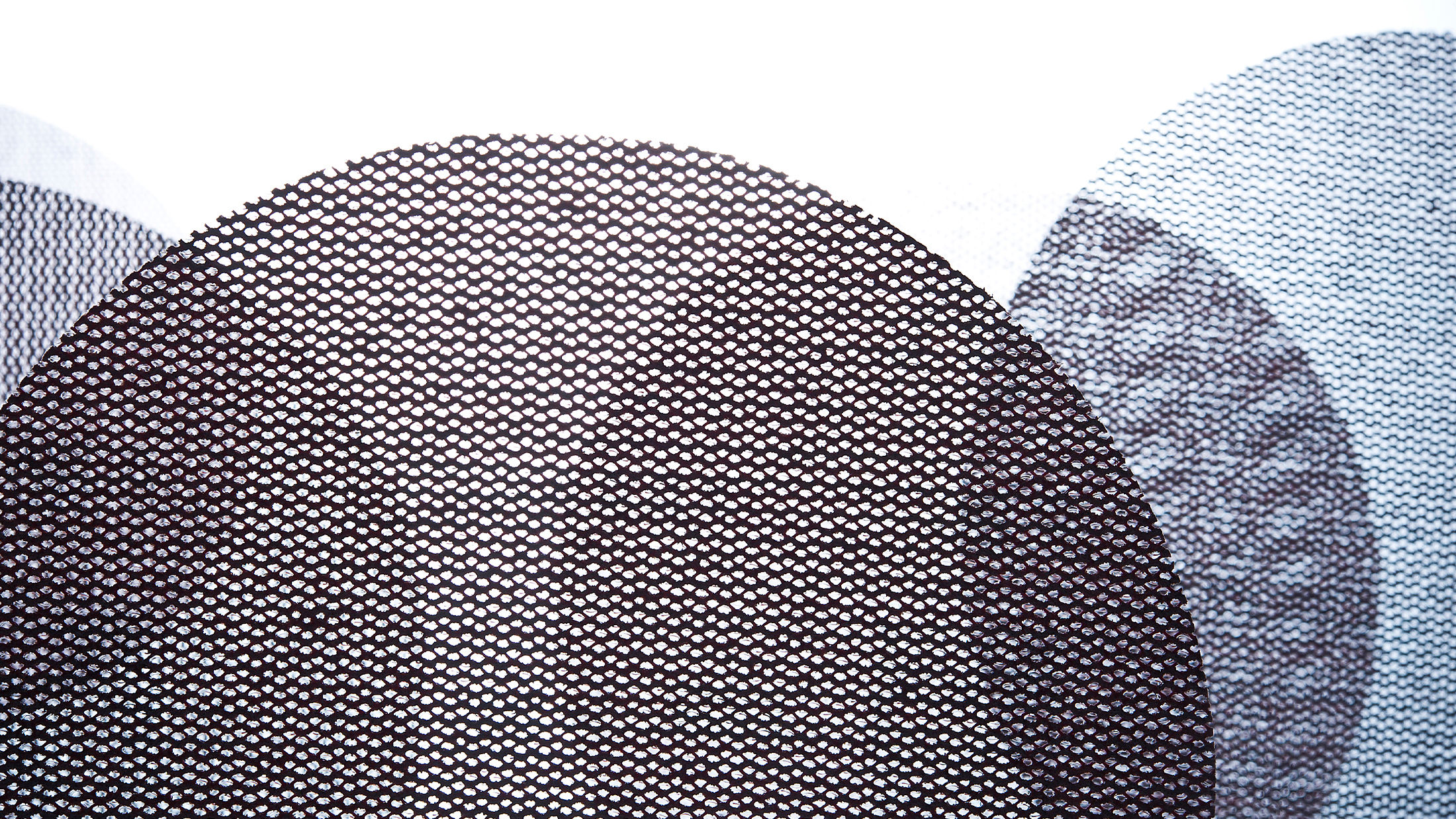

A key element of its business is the manufacture of the wooden volumes. Rockcity owner Mark English explains, “The Birch plywood enables a more structural hold to be produced which is then painted with resin and aggregate to achieve a rock-like finish. In order for the volumes to be smooth to the touch they need to be finished to perfection. Following a recommendation from a colleague who was using an earlier model, this year we transitioned to a Mirka DEROS sander in combination with the Mirka Abranet® Ace and 150mm Mirka® Galaxy abrasives with a 1230L Mirka® dust extractor.”

Mark adds, “When manufacturing holds, we first make a master out of fibre glass or polyurethane, a process which starts with a chain saw and a hand saw and is then finished by hand to produce the ergonomic, smooth, artistic shape required of the final piece. The DEROS is anti-static, kind on the hands and arms because of its low vibration benefits, and the extractor takes the fine dust off the job and in the air, which is very important. It also has a good capacity which means we are not breaking the flow of the job and the discs last a very long time, so there is no interruption. We’re very pleased with the products and are beginning to transition the work we have previously outsourced to specialist companies inhouse. The initial investment is significant, but the high-quality result is paying dividends. Such is the recognition of the Mirka solution, the combination of products has now become the ‘go-to’ system for the climbing industry.”

So where next for Rockcity? The company already supplies most of the climbing World Cups and high-end sports events and its sights are now set on the Paris Olympics in 2024. The company is embracing other industries to introduce fresh ideas that will enable it to innovate and deliver more prototyping and production. Mark concludes, “With one of our volumes already in the Olympic Museum, we’re confident that the Mirka tools will enable us to continue to push the boundaries of the sport and lead the way in product development and legacy knowledge.”