Register Your Tool

All Mirka power tools have a standard two-year warranty. Get an additional 1 year of warranty free of charge by registering your tool within 30 days of purchase.

Keep your tools in excellent shape on myMirka where you can register your tools.

Replenish your stock, access marketing materials, view sales guides and read about upcoming product launches.

Processes or products are only good when they are used properly and appropriately. We want to help you get the most out of your abrasives by using the correct product for the job at hand. With decades of experience, we recognise the importance of productivity and a flawless finish. Here are some common problems when sanding and how to solve them.

We want to stop abrasives from clogging up prematurely – this will help reduce the amount of abrasives you are using – reducing costs. Our top tips for solving this problem…

• Check that the paint, lacquer, or filler is properly cured.

• Avoid sanding with grits that are too fine.

• A stearated product is usually the best choice for paint or lacquer.

• Use machines with dust extraction and ensure the hole combination on the backing pad is compatible with the abrasive.

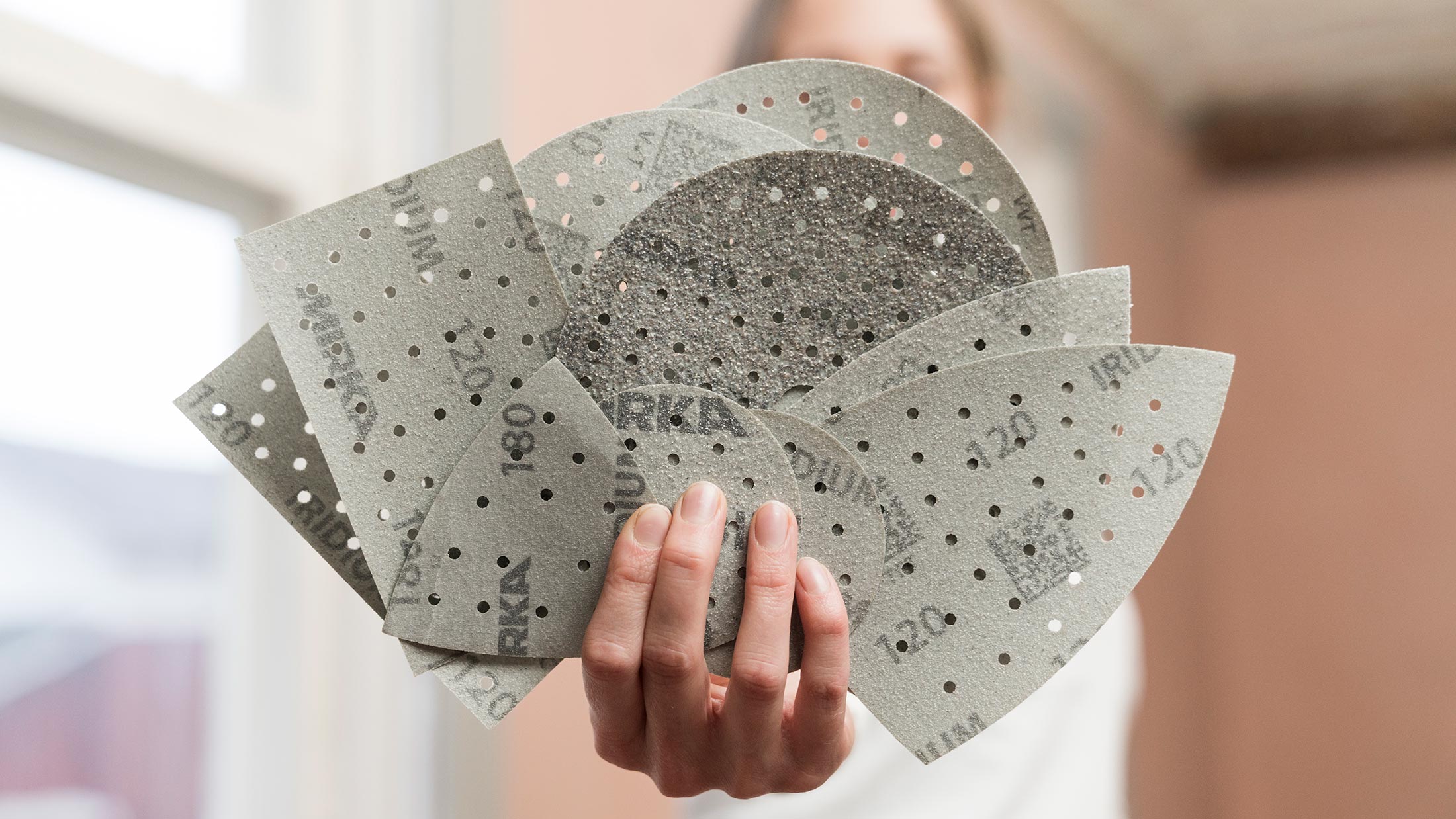

Visible finger marks ruin a flawless finish and require further sanding, costing you more time. Mirka has special abrasives specifically developed to reduce the risk of finger marks, including Goldflex Soft and Mirlon Total™.

Foam-backed abrasives are great for sanding profiled surfaces as they distribute the sanding pressure evenly.

Skipping grits when working through the process can result in visible scratches once you have applied lacquer. To rectify this, you would need to do a lot of rework so it is best to try and avoid this happening to start with. Our top tips include…

• Avoid too big a step between grits.

• A silicon carbide abrasive will usually give a better surface finish.

• Use a random orbital sander such as the Mirka® DEROS.

Inefficiency is costing you time and money. Feel like you have been sanding for way too long and seeing little difference? Let's take a look at your abrasives.

• Start with a coarse grit and work towards finer grits.

• Aluminium Oxide abrasives tend to have a better cut.

We hope this has given you an insight into how to make your abrasives work better for you. Processes or products are only good when they are used properly and appropriately. If you are having issues with your sanding processes, our team of technical experts can demonstrate flexible solutions from the extensive Mirka range of sanding products.

Receive the latest news

Want to keep up to date with what's happening at Mirka?

You can sign up for our quarterly here!