Register Your Tool

All Mirka power tools have a standard two-year warranty. Get an additional 1 year of warranty free of charge by registering your tool within 30 days of purchase.

Keep your tools in excellent shape on myMirka where you can register your tools.

Replenish your stock, access marketing materials, view sales guides and read about upcoming product launches.

It is easy to forget how much surface area needs to be prepped on cabs and trailers when prepping them for paint. This is why it is important that the jobs are completed efficiently while ensuring a high-quality finish that makes the painting part of the process as easy as possible.

Stephen Reynolds, bodyshop manager, Truck East Scania discusses the importance of investing in the correct products and how they help with overall efficiency.

“Tools and abrasives are the lifeblood of any workshop, and it’s no different for us. We are always reviewing and researching products that can benefit our business and one of the areas we investigated was upgrading our sanders and abrasives. During this process we were introduced to Mirka via one of our suppliers, although we were already aware of the brand through our peers. So, we decided to bring them in and see what they had to offer.

Upon bringing them on site, we got an understanding of the breadth of products that were in Mirka’s portfolio and seeing several relevant products being used in our processes, we decided to take the plunge and invest in mobile dust-extraction systems, abrasives and sanders.

Sanders are used for many hours on our floor, so it’s important to have tools that produce fewer vibrations and are built with the user in mind, which is where the Mirka® DEROS comes into play for us. The fact this tool is lightweight means that it reduces the stress on the joints of our technicians because they do not have to manhandle the tool around large surface areas every day. In addition, with sanders there are vibrations but the reduction we have seen since using Mirka tools has dramatically reduced and we hope to reduce risk of exposure to our staff.

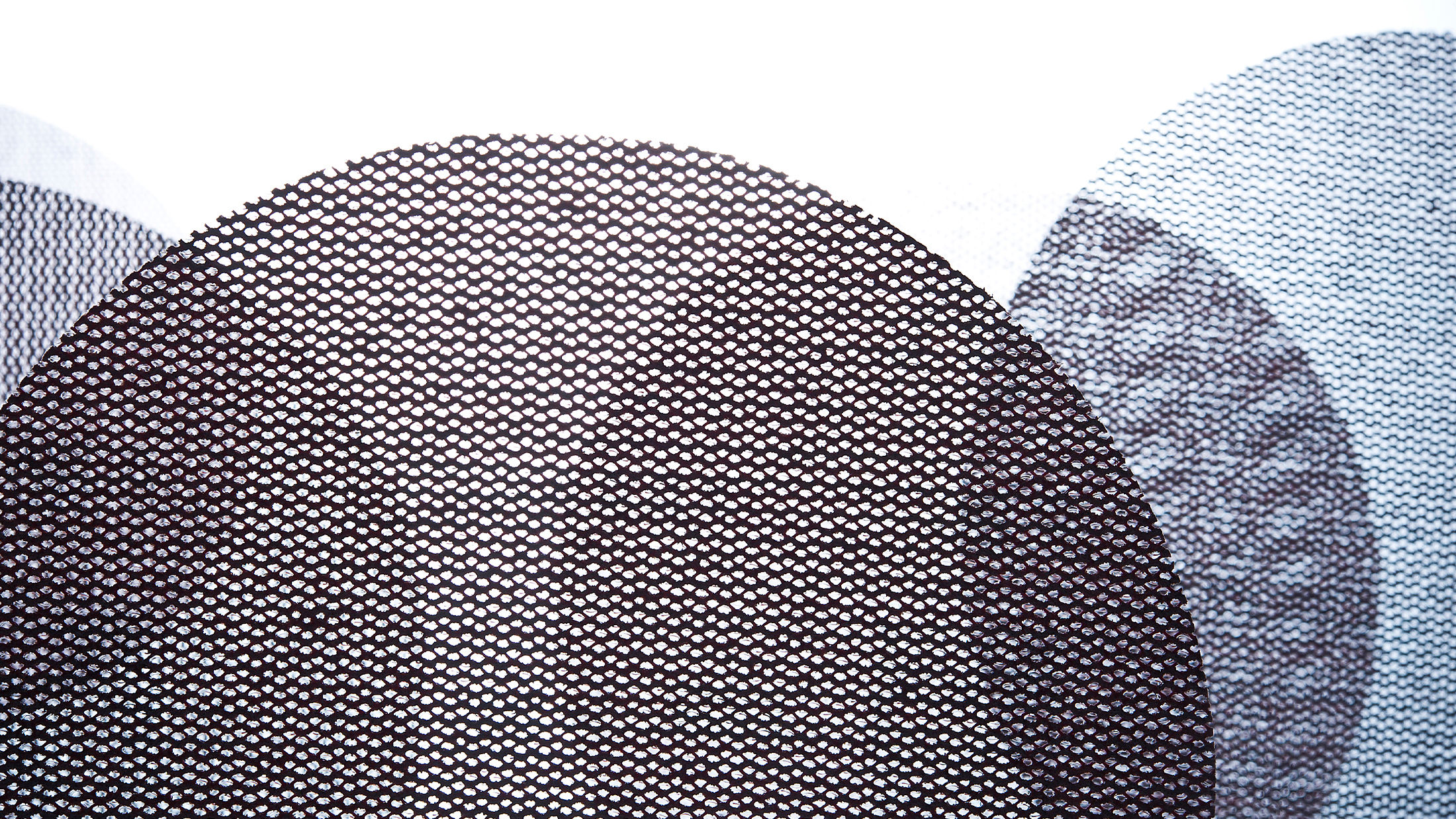

For the abrasives, we noticed that we were going through what felt like loads of discs which was not cost-effective in the short, medium and long term. Since moving over to the Mirka Abranet® abrasive range, our technicians have noticed several benefits from day one. The first is the fact that they are suitable for use across multiple applications, so our technicians do not have to change the abrasive depending on the work they are doing. The second is they are high quality and hardwearing, so they provide the same consistency of cut, whether it is the abrasive’s first or hundredth use. In addition, we took the opportunity to streamline our core abrasives list with the help of Mirka. The reason we did this was because we decided we did not want to carry any products that were not required for our processes, and we knew that if there were one-off jobs that required a different grit to what we had we could easily bring it in.

In a workshop like ours, one of the main jobs we do is prepping cabs for paint and we must have been producing kilos of dust a week. The issues this created were contaminated surfaces and an increased amount of time our technicians spent clearing the dust after each job. To combat this, we invested in mobile dust extraction systems. These units do not take up a lot of space on the floor and when combined with Mirka’s tools and net abrasives they ensure we have a dust-free work environment. Having these systems means our shops are cleaner and more efficient, our technicians are happier, and we have significantly reduced the risk of contaminated surfaces, so less reworking is required. In addition, having what can be described as a cleaner prep, leads to a better end result.

Another way our team has increased the efficiency of our trailer and cab prep processes and the key-to-key times of these jobs is through the completion of training that Mirka has put on for our business. The training we have received has not been generic, it has been customised to the needs and requirements of the business and our technicians. The training was on site, which enabled our technicians to see how the tools and abrasives handle our work, so processes are more efficient and cost-effective. This means that the savings we are making from using products to the best of their abilities can be invested back into the business.

Overall, it’s important to constantly refine processes with the help of partners because in the long run, it helps increase productivity as well as overall efficiency.”

This case study also appeared in Commercial Vehicle Workshop.