Register Your Tool

All Mirka power tools have a standard two-year warranty. Get an additional 1 year of warranty free of charge by registering your tool within 30 days of purchase.

Keep your tools in excellent shape on myMirka where you can register your tools.

Replenish your stock, access marketing materials, view sales guides and read about upcoming product launches.

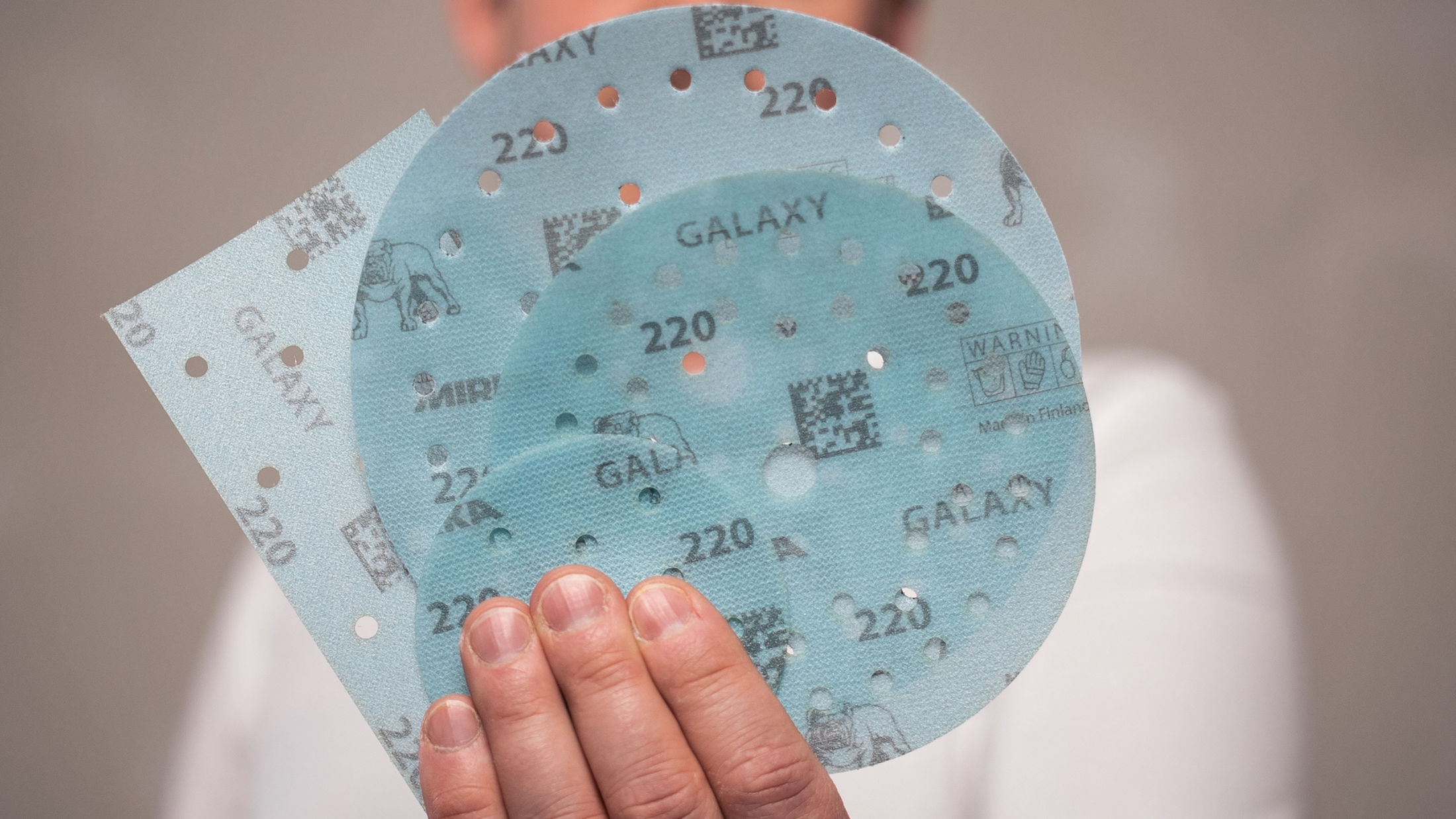

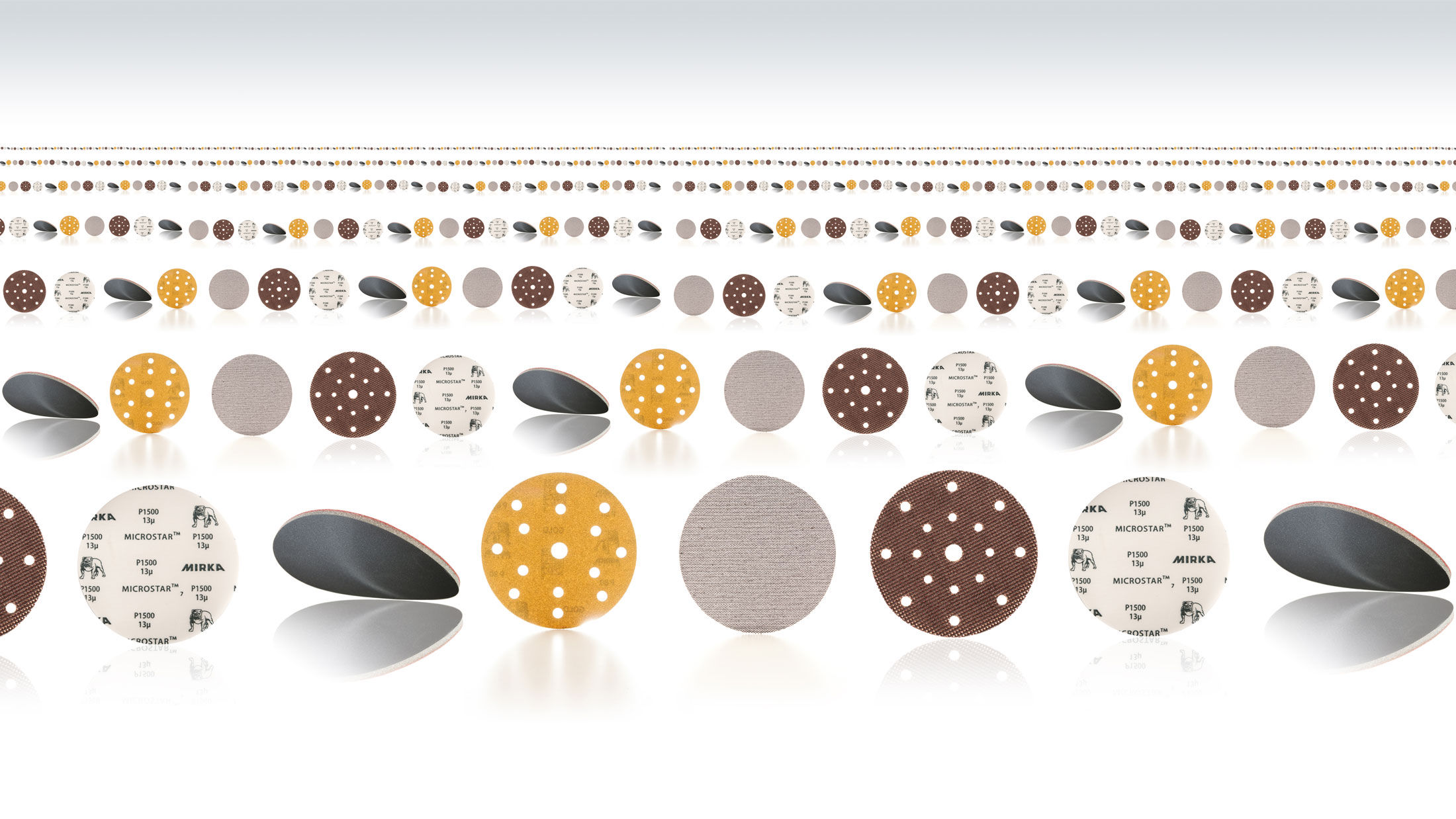

Crafting the perfect abrasive involves a delicate balance of factors, from the size and properties of the abrasive grains to the composition of the adhesive and backing materials. At Mirka, we understand these complexities like no other, offering a comprehensive range of technically superior and high-quality abrasives for all kinds of sanding applications. Let’s take a closer look at the building blocks of abrasives.

When it comes to sanding the choice of abrasive grain is vital, both for the end result and to achieve the best possible lifespan from the product. Choosing a sharp grain will achieve a good cut. However, if a finer surface finish is essential then another type of grain may be chosen. The grain selection process is also affected by the strength required.

Aluminium Oxide: The most common abrasive grain for sanding is aluminium oxide – the grains are sharp and tough enough for most applications.

Silicon Carbide: Compared to aluminium oxide, silicon carbide is more regular in shape and is not as brittle. The strength of these abrasive grains makes it perform well on hard surfaces. In addition, the shape of the silicon carbide grains produces a better surface finish compared to aluminium oxide, which makes them more suitable for intermediate sanding.

Ceramic: Special ceramic grains can form new abrasive edges when they wear down so you can continue sanding for longer. Ceramic abrasives are designed for hard materials and coatings such as hardwood or solid surfaces.

It is important to note that both the surface structure and surface finish are affected by the choice of grains. This means that the colour of the treated surface may vary. The minerals used for Mirka products are synthetic, making them harder and more durable compared to natural sand.

The performance of abrasives is greatly affected by the number of abrasive grains used. For example, fewer grains result in an open coating which is highly resistant to clogging, whereas more grains produce a closed coating with good stock removal and a smooth surface finish.

Different grit sizes are used for different purposes. Therefore, grit sizes are sorted during manufacture by passing them through sieves. When looking at the grit numbers, a lower number is more coarse and as numbers increase, the abrasives are finer. For example, P80 is coarser than P320, and P3000 is very, very fine in comparison.

Some abrasives receive a special stearate coating treatment which is designed to prolong lifespan. Usually, the stearate is based on zinc or calcium and is like small flakes applied on top of the abrasive. As the stearate coating is worn off during use it prevents clogging and gives the abrasive a longer lifespan. The stearate reduces the initial cut and, therefore, produces a more consistent surface finish over the lifetime of the product.

Typical Mirka stearated products include Gold, Q.Silver, Abranet® and Sica Fine Stearate. Stearated products achieve the best results when sanding paint, lacquer and similar surfaces. For coarse sanding with high sanding pressure (for example, wood sanding with wide belts), stearate provides no advantage because it is very quickly worn off.

Generally, there are two types of fastening systems – ‘PSA’ (Pressure Sensitive Adhesives) and ‘Grip’. PSA uses an adhesive that is permanently tacky in dry form. With only light contact or hand pressure, PSAs adhere firmly to a variety of different surfaces which makes them ideally suited for fastening discs and similar products to an even backing pad.

The grip fastening system is a hook and loop material attached to the backing of the abrasive. The loops on the abrasive backing join with the hooks on the backing pad to fasten the two together. For example, Mirka’s Net Sanding products are constructed with loops integrated into the backing material.

Selecting the right abrasive for your specific application can be daunting, but it doesn't have to be. Mirka's team of technical experts stands ready to offer personalised guidance and support, whether you require on-site demonstrations or consultations. With the right abrasives in your toolbox, you can minimise waste and maximise efficiency.