Register Your Tool

All Mirka power tools have a standard two-year warranty. Get an additional 1 year of warranty free of charge by registering your tool within 30 days of purchase.

Keep your tools in excellent shape on myMirka where you can register your tools.

Replenish your stock, access marketing materials, view sales guides and read about upcoming product launches.

Made to order belts for any application

Introducing....

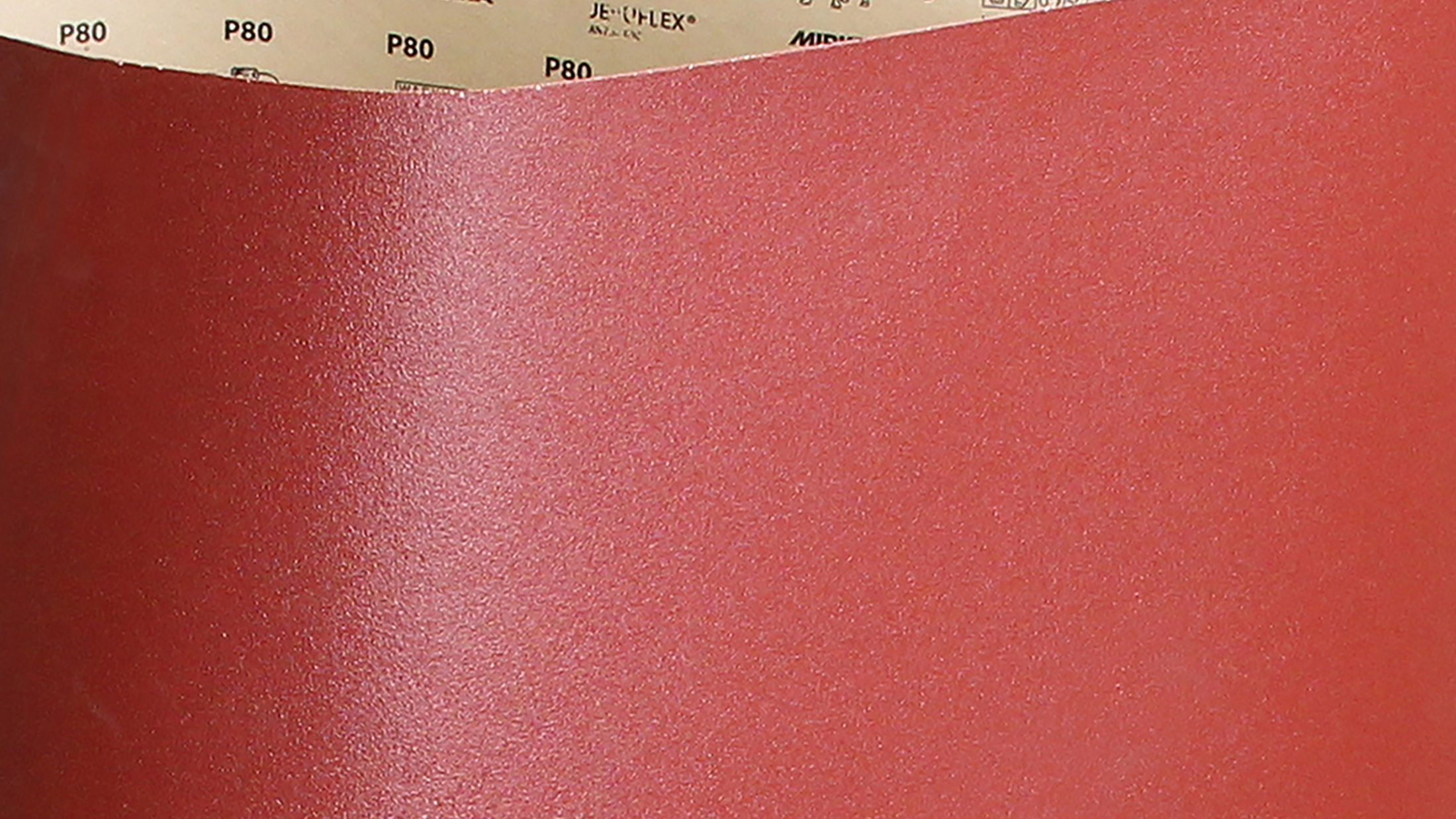

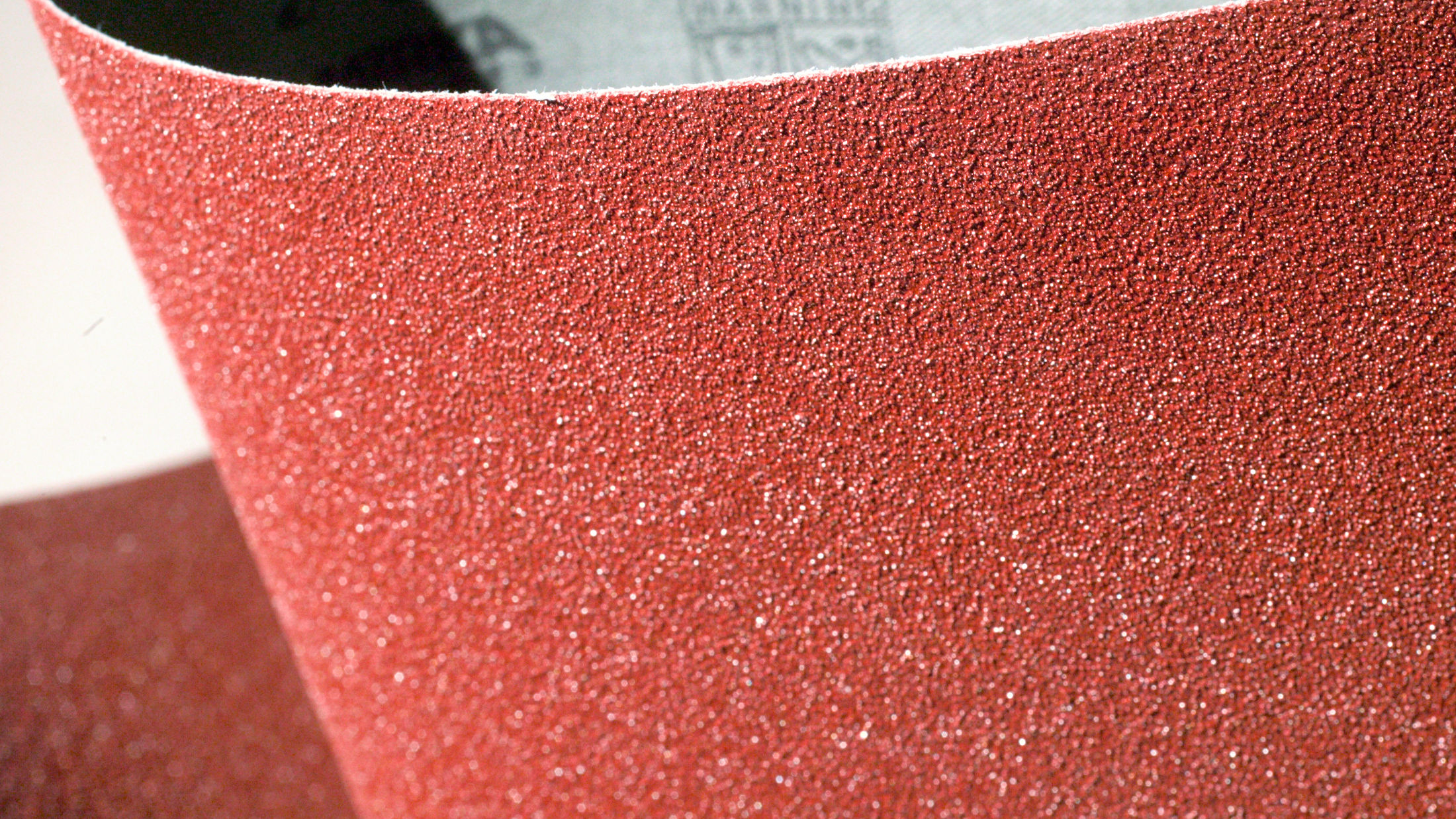

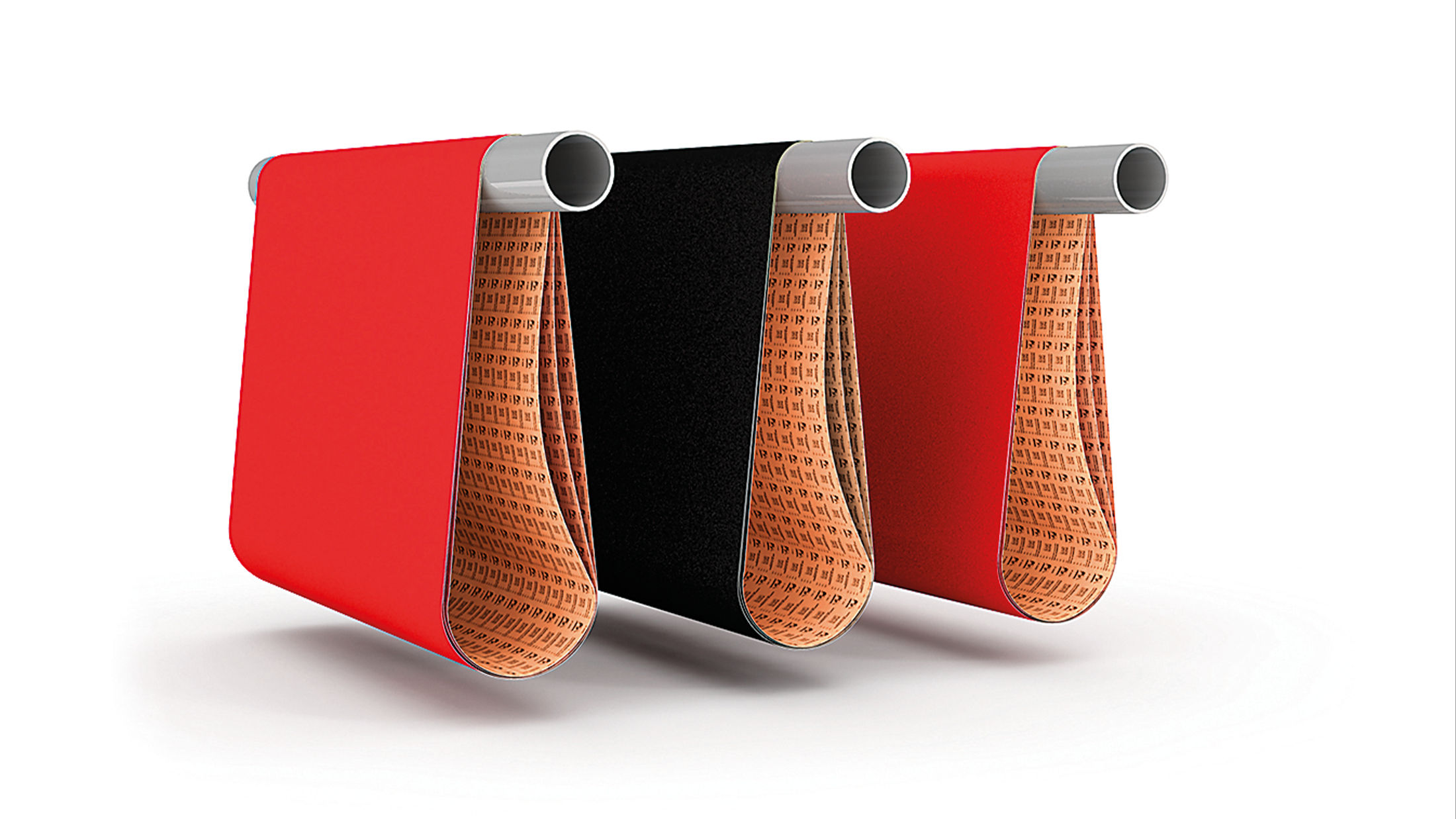

Ultimax® Black delivers exceptional sanding quality from start to finish. Its patented manufacturing technology and antistatic properties take belt sanding to the next level in longevity and sanding performance thanks to its strength and stability, achieving consistent finishing without the need to adjust machine pressure over time.

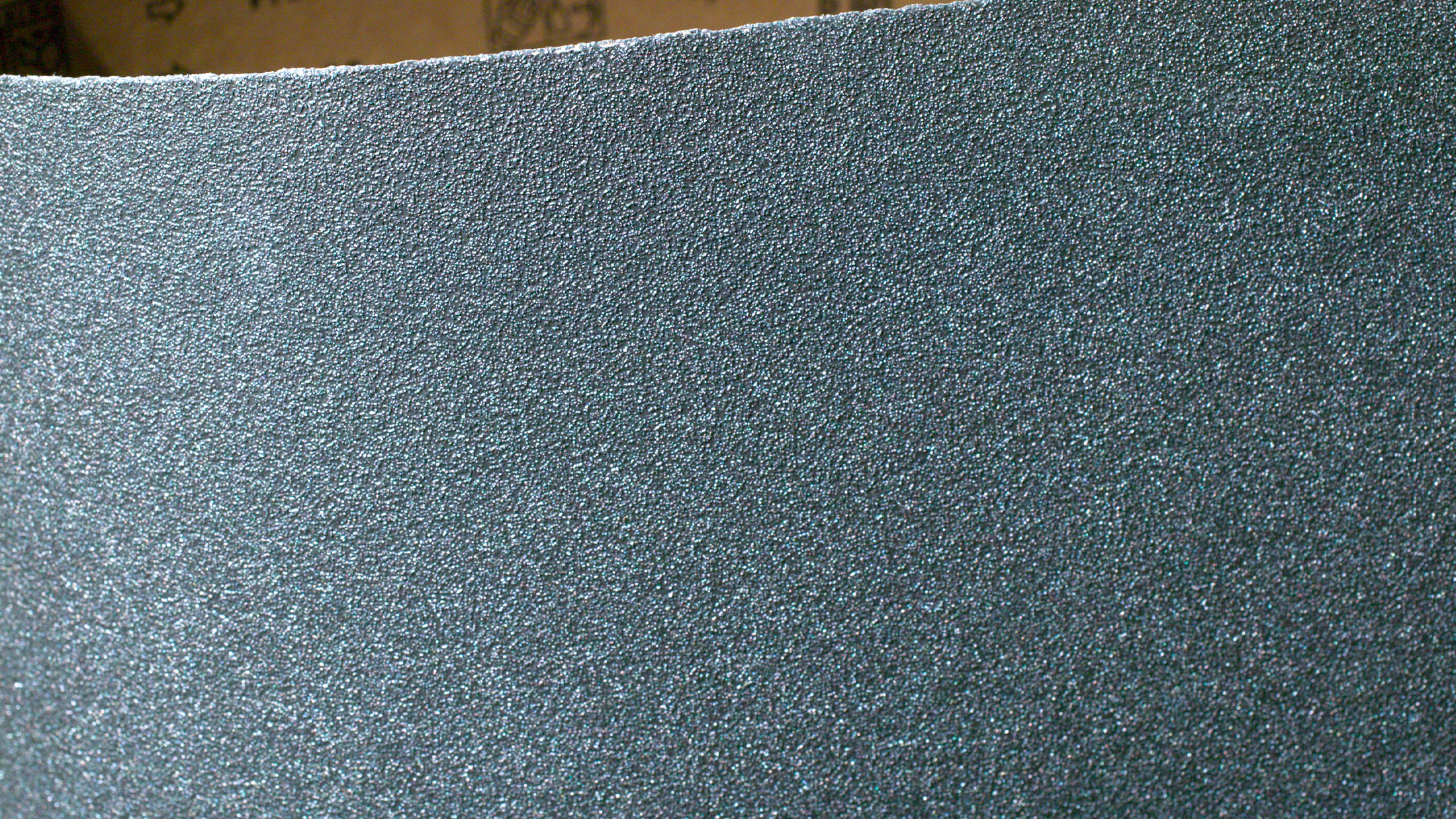

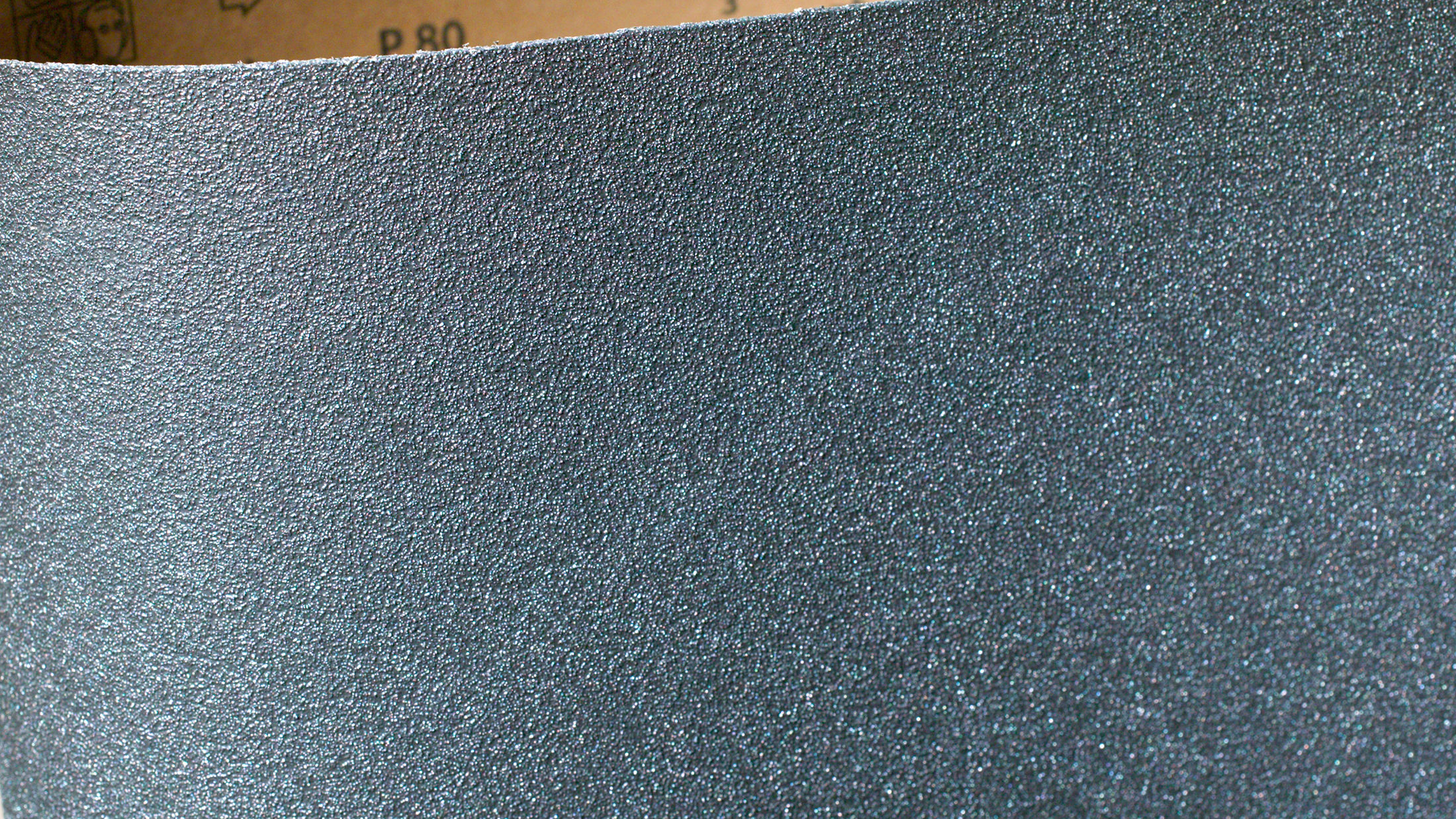

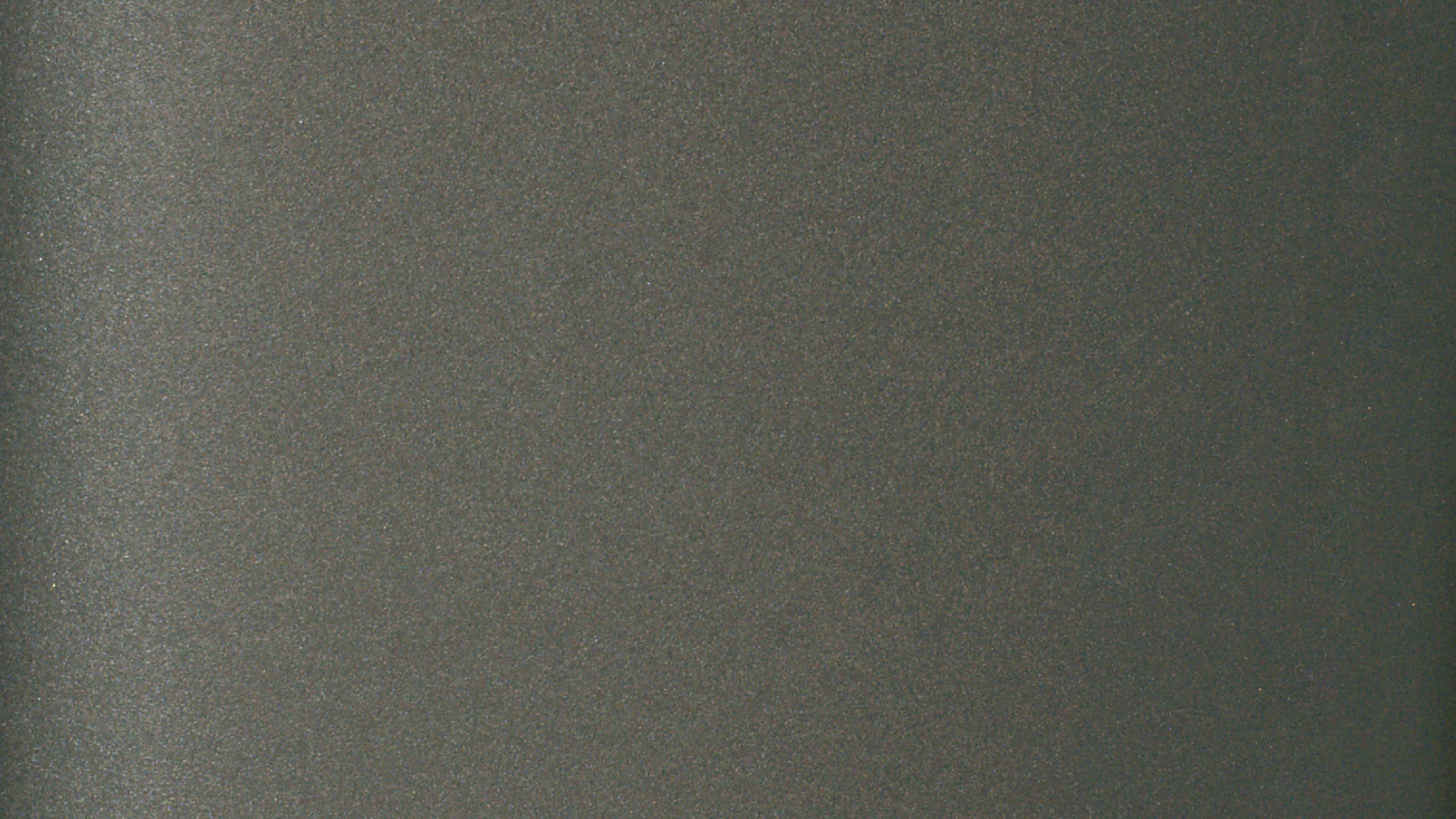

Choose the right belt for your surface

Choosing the appropriate sanding belt can be a challenge, you want to make sure to have the optimal abrasive for your sanding application and surface, otherwise you can damage both the surface and your belt sander.

Here you can learn more about what kind of belt we recommend for your surface for the job.

Learn more about what belt we recommend for different surfaces

Mirka have an arsenal of quality wide belts to choose from as well as a team of wide belt specialists.

Achieving the desired final result with any surface treatment is affected by a wide variety of factors. For example, the choice of sanding material plays a vital part in the overall process. By choosing the correct type of sanding material and handling it correctly, you can ensure that you achieve an optimal sanding result, as well as the best possible lifespan for the sanding material itself.

Choose the right belt to make more

Overall sanding costs can be minimised simply by choosing the most suitable

product for each sanding operation. That means:

Optimising belt lifespan with the right application

The lifespan of the belt can be further increased by ensuring that the sanding

equipment is correct and used properly:

Performance through innovation

Ultimax wide belts are like no other.

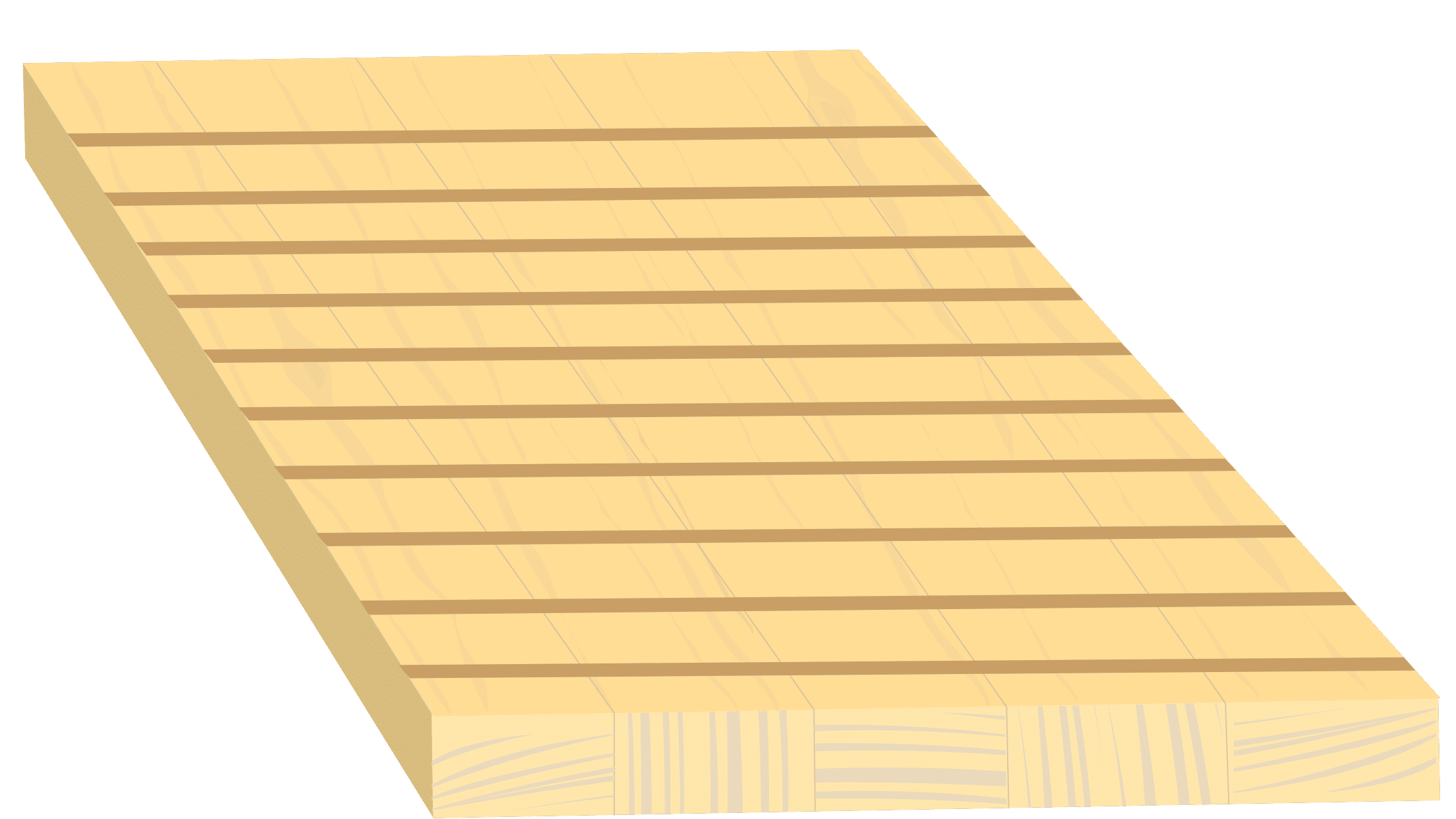

The innovative cavities force air between the surface of the work and the belt, which keeps the sanding temperature low, prevents burning and extends the life of the belt.

This innovative new technology, along with the special abrasive grains that are used, gives a longer product lifespan and reduces material usage per job.

We offer on-site demonstrations

At the frontline of the business, we believe that training, shared knowledge, quality products and systems make a better place to work for the individual.

To support this Mirka has a national team of trained staff who have a wealth of industry experience and are able to provide a hands-on approach to support businesses.

Technical Wide Belt Specialists

A customer producing solid oak wood flooring and using wide belts from our competitors were experiencing random marks in the wood after limited sanding. After several attempts from the current supplier to resolve the issue they decided to call in the wide belt machine repair company who immediately got in contact with Mirka to assist. The marks were caused by hard spots of silicon embedded in random parts of the oak, caused by an unnatural occurrence in the Parenchyma Cells within the oak tree during growth. These hard spots when sanded with standard Aluminium oxide belts cause damage to the belt which then transfers to the oak panel each time the belt passes over it. To resolve the issue, we supplied a close coated Silicon carbide grain belt, which is much harder and capable of sanding through the hard spots without damaging the belt.

>> P36–P80: Polyester cloth backing

>> P100–P240:X-weight cotton cloth backing

>> Aluminium oxide

>> Semi open

Hard Wood (also Melamine)

>> P40–P320

>> Antistatic T- and F-paper backing

>> Aluminium oxide

>>Closed with Selective coating® technology

Hard Wood (also Melamine)

>> P36 - P400

>> Antistatic T and F paper backing

>> Aluminium oxide

>> Closed

Soft Wood

>> P40, P60–P240, P320

>> Antistatic T- and F-paper backing

>> Aluminium oxide

>> Open

Soft Wood

>> P80–P180

>> Fully antistatic

>> F-paper backing

>> Silicon carbide

>> Open

Soft and Hard Wood

>> P80–P220

>> Fully antistatic

>> F-paper backing

>> Aluminium oxide

>> Semi open

MDF / HDF

>> P80–P220

>> Fully antistatic

>> F-paper backing

>> Silicon carbide

>> Closed

Intermediate Sanding

>> P240–P1500

>> Fully antistatic

>> E-paper backing

>> Stearate

>> Silicon carbide

>> Semi open

Intermediate Sanding

>> P240–P800

>> Antistatic

>> E-paper backing

>> Stearate

>> Aluminium oxide

>> Semi open

Intermediate Sanding

>> P360–P2500

>> Polyester film backing

>> Aluminium oxide

>> Semi open

>> Narrow belt

Top-Coat Sanding Prior to Polishing

>> P360–P2500

>> Polyester film backing

>> Aluminium oxide

>> Semi open

>> Narrow belt

Top-Coat Sanding Prior to Polishing

>> P180–1200

>> Polyester film backing

>> Aluminium oxide with ceramic coating

>> Semi open

>> Narrow belt

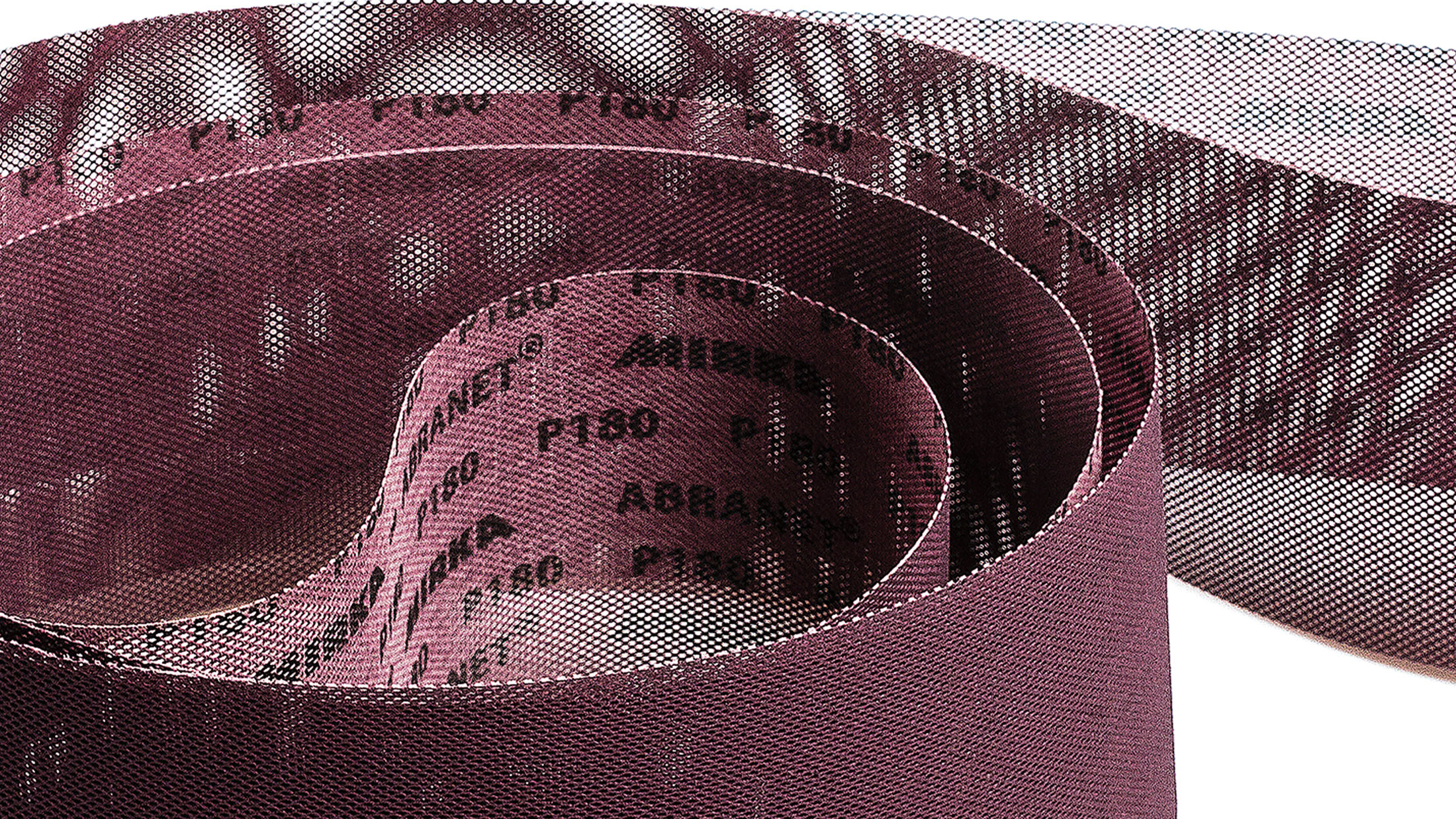

Flat Profiles

>> P80–P240

>> PA net backing

>> Aluminium oxide

>> Closed

>> Narrow belt

Contoured Profiles

>> P60–P400

>> J-weight cotton cloth backing

>> Aluminium oxide

>> Semi open

>> Narrow belt

>> Grits P80, P100 & P150

>> Y cloth polyester backing

>> Zirkonium Oxide

>> Closed Coating

Recommended grit size use

In general, the first sanding belt is used for stock removal, while the following

belts are only used for creating an even surface finish.

| Grit size | Use |

| P24-P80 | Coarse sanding, calibration |

| P100-P320 | Medium sanding, wood sanding |

| P320-P1200 | Fine sanding, intermediate sanding |

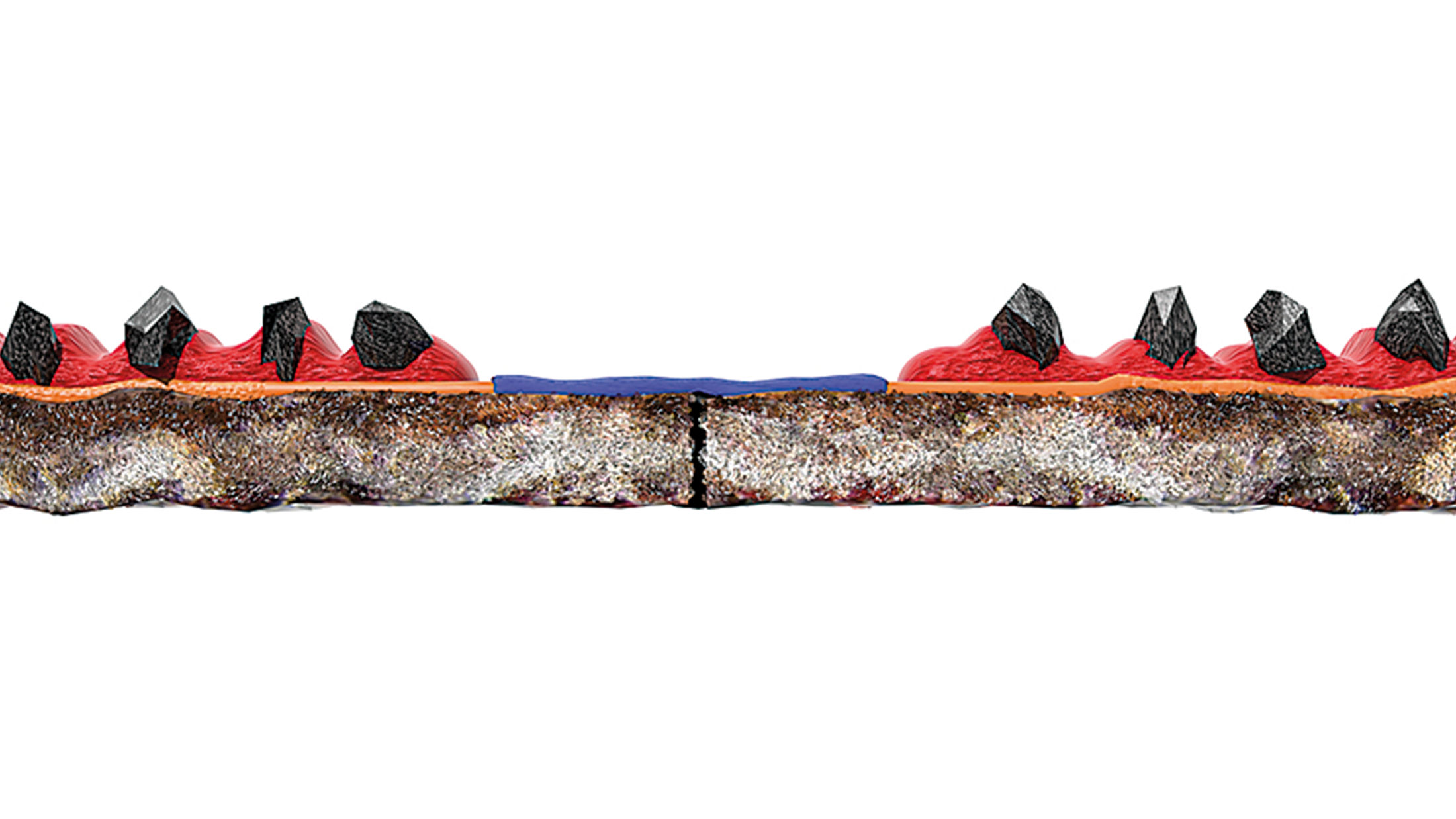

Belt joint performance is a key factor for sanding belts. The joints must be as

strong as the actual sanding material and should not be too thick or too thin

compared to the sanding material. The belt should also have the right shape and dimension.

Mostly used for sanding belts made from paper, an A-joint is an overlapping

joint without compensation on the abrasive side, e.g. without interruption in the

coating. It produces a uniform sanding belt thickness, even across the joint, and

results in an even sanding finish without chatter marks.

The most common joint for sanding belts with cloth backing, the B-joint is an

overlapping joint with compensation on the abrasive side. This means that the joint area is free of abrasive material which allows the cloth to overlap without the joint having to be thicker than the rest of the belt. The B-joint is also suitable for special paper products, such as Mirka’s Ultimax.

Typically used for small cloth belts that require strength and flexibility, a

T-joint is cut through the sanding belt without an overlap and the joint is attached with tape on the reverse side.

A TS-joint is similar to a T-joint but is different in the way the connecting ends are cut. By using a TS-joint the hinge effect can be avoided. This joint type is most suitable for belts in medium grit sizes and it is most common on cloth-backed belts, although TS-joints can also be found on paper-backed belts.

This is a special joint where the tape is applied on the sanding side making it suited to profile sanding with a sanding pad.

By simply following some basic recommendations on wide belt storage, you can ensure that the belts remain undamaged and maintain their full working potential.

>> Store belts in their unopened packages until they are to be used.

>> The belts can be hung horizontally prior to use in order to make handling easier.

>> The correct storage temperature is 15–25°C.

>> The relative humidity is recommended to be 35–60% and wide belts should have even moisture over the whole width.

>> Avoid keeping belts hanging close to a cold wall or a heating source.

>> Do not expose the abrasive belts to direct sunlight

Having challenges with wide belt sanding?

You have invested in a wide belt sanding machine, it can be frustrating when you are not getting the results you expect.

This section describes typical problems that might occur when using wide belts. It is essential to understand where a problem originates from in order to correct the process.

Achieving the desired final result with any surface treatment is affected by a wide variety of factors. We can help you achieve an optimal sanding result, as well as the best possible lifespan for the sanding material itself.

A belt for every application

It is now possible to calculate the price of any narrow or wide belt using the Mirka Belt Calculator.

Simply select the Abrasive material, grit, width and length of the belt required to get an instant price.

CHATTER MARKS IN CROSS DIRECTION

>> Check the condition of the belt joint.

>> Is the machine working as it should? In particular, a malfunctioning drum can cause chatter marks.

>> Wrong type of sanding unit? A hard drum with a short sanding contact patch is more likely to result in chatter marks, compared to a soft sanding pad.

POSITIVE STRIPES

(Stripes coming out of the wood piece)

>> Narrow stripes in a pattern following the belt oscillation?

These are normally caused by sharp objects in the work piece which destroy the abrasive.

Change the belt and examine the work pieces for sharp objects.

>> Wide straight stripes? Typically a problem with sanding drums or pads. Clean the pad and have the drum calibrated.

NEGATIVE STRIPES

>> Wide straight stripes? The most common problem is dust on the sanding pad. Clean the pad or, if necessary, change the graphite cloth.

>> Narrow straight stripes? It is possible that small wood pieces or dust are stuck to the pressure shoe. Clean the machine.

BROKEN BELTS

>> Check the oscillation of the machine and clean inside the machine.

>> Check the storage of the belts (see page ‘Wide belt storage’).

>> Avoid too much stock removal. Avoid using clogged belts.

>> Check the condition of the belt joint.

UNEVEN SURFACE

The surface feels uneven?

>> Steps too big in grit sequence.

>> Stock removal with sanding unit which has a sanding contact that is too soft.

SHORT LIFESPAN

>> Avoid too much stock removal per sanding unit – check machine adjustments.

>> Make sure you are using the correct product and grit sequence.

>> Make sure the cleaning system and the dust extraction is operating correctly.

>> Use the whole belt width when sanding.

Mirka have an arsenal of quality wide belts to choose from as well as a team of wide belt specialists.

Achieving the desired final result with any surface treatment is affected by a wide variety of factors. For example, the choice of sanding material plays a vital part in the overall process. By choosing the correct type of sanding material and handling it correctly, you can ensure that you achieve an optimal sanding result, as well as the best possible lifespan for the sanding material itself. Choose Mirka’s unique sanding solutions for coarse and bare wood sanding, Intermediate sanding of paint or lacquer or sanding of top coat before polishing.

Do you want to know more?

Please get in touch and our expert support team will answer your questions.