Reach the optimal finish with a minimized scrap rate

Answer to the Challenge

A driving force in turbine development is improved energy efficiency both in the finished product as well as at the manufacturing stage. This leads into increasingly complex three-dimensional shapes, resulting in challenges in meeting consistent quality requirements with conventional manual finishing methods.

Mirka’s force-controlled finishing technology is suitable for different large blade applications, ranging from jet engines to gas and steam turbines, where extreme precision is key. As a result, both the desired finishing quality and minimized scrap rate can be reached.

Automated finishing process in a controlled environment

7-Axis Robotized Platform

Mirka utilizes a 7-axis robotized platform for large blade finishing in a wet process environment, which is a requirement due to the highly flammable dust created from sanding turbine blade material. The resulting uniform surface quality minimizes process waste and scrap rate, with increased yearly production capacity.

As an added bonus, the automated process reduces strain on the operator, as the entire robot cell is software controlled.

Suitable for large and heavy workpieces

Linishing Cell

The platform allows for large and heavy workpieces of up to 1,800 mm in length and with a maximum weight of 500 kg. Multiple robots can work together in the same system, which reduces the time to completion. Meanwhile, the operator can safely install a new workpiece outside the cell.

The cell features a patented 30 x 3,500 mm L-series belt grinder for large surfaces.

- Wet process environment

- Tool to part working method

- Special belt tool with 3500mm length belt

- Active belt guidance monitoring

- Integrated tool center point calibration and part position measurement

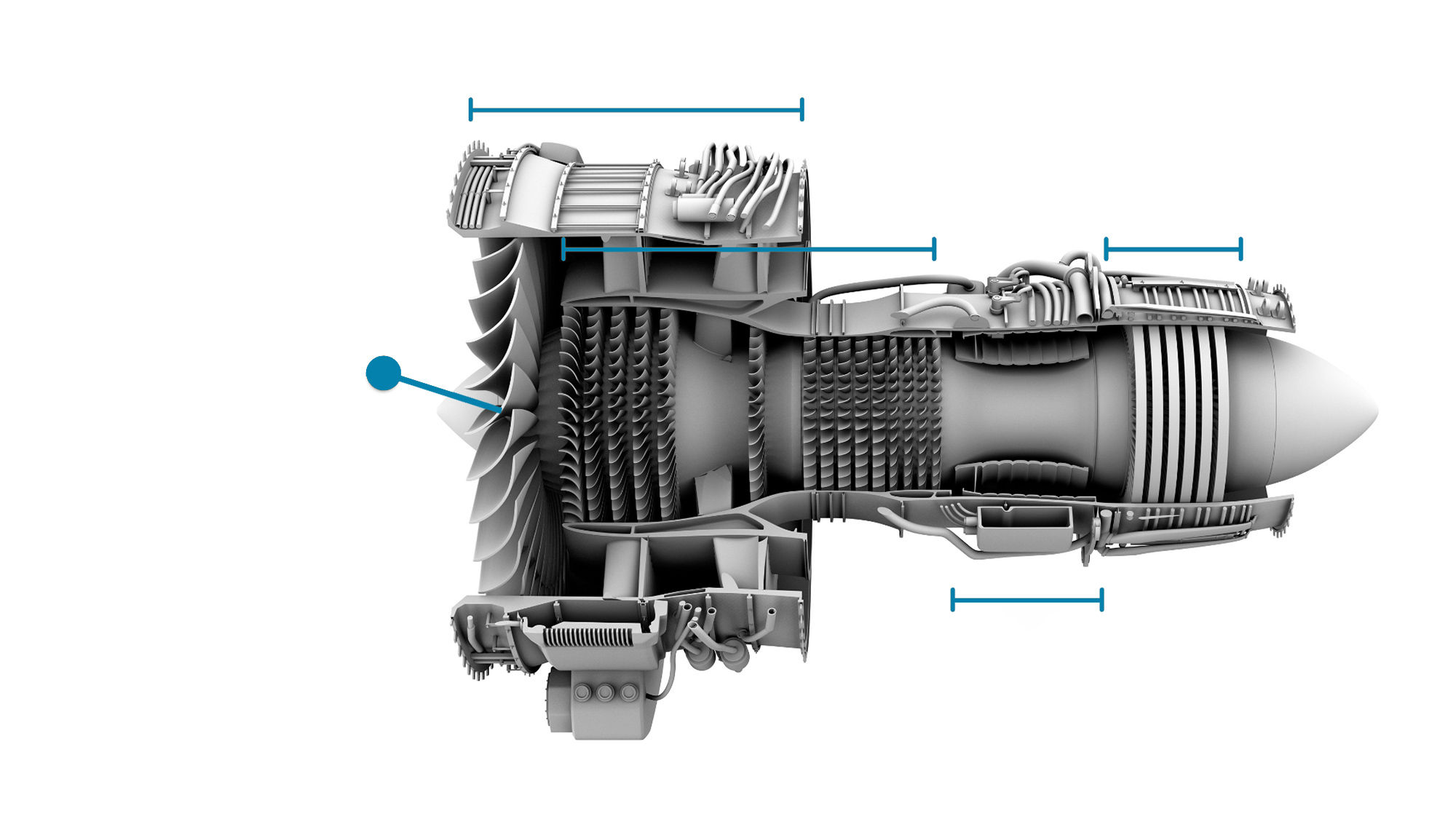

Sections of a Jet Turbine

Start Planning Your Turnkey Solution

Our skilled team will help you design an automation solution perfectly tailored to your surface finishing needs. From us, you’ll get not only modern robotic cells, but also robotic tools, abrasives, and other accessories to help you maximise the potential of your automation solution.