2+1 years

Register Your Tool

All Mirka power tools have a standard two-year warranty. Get an additional 1 year of warranty free of charge by registering your tool within 30 days of purchase.

Keep your tools in excellent shape on myMirka where you can register, manage and order repair for your tools.

Replenish your stock, access marketing materials, view sales guides and read about upcoming product launches.

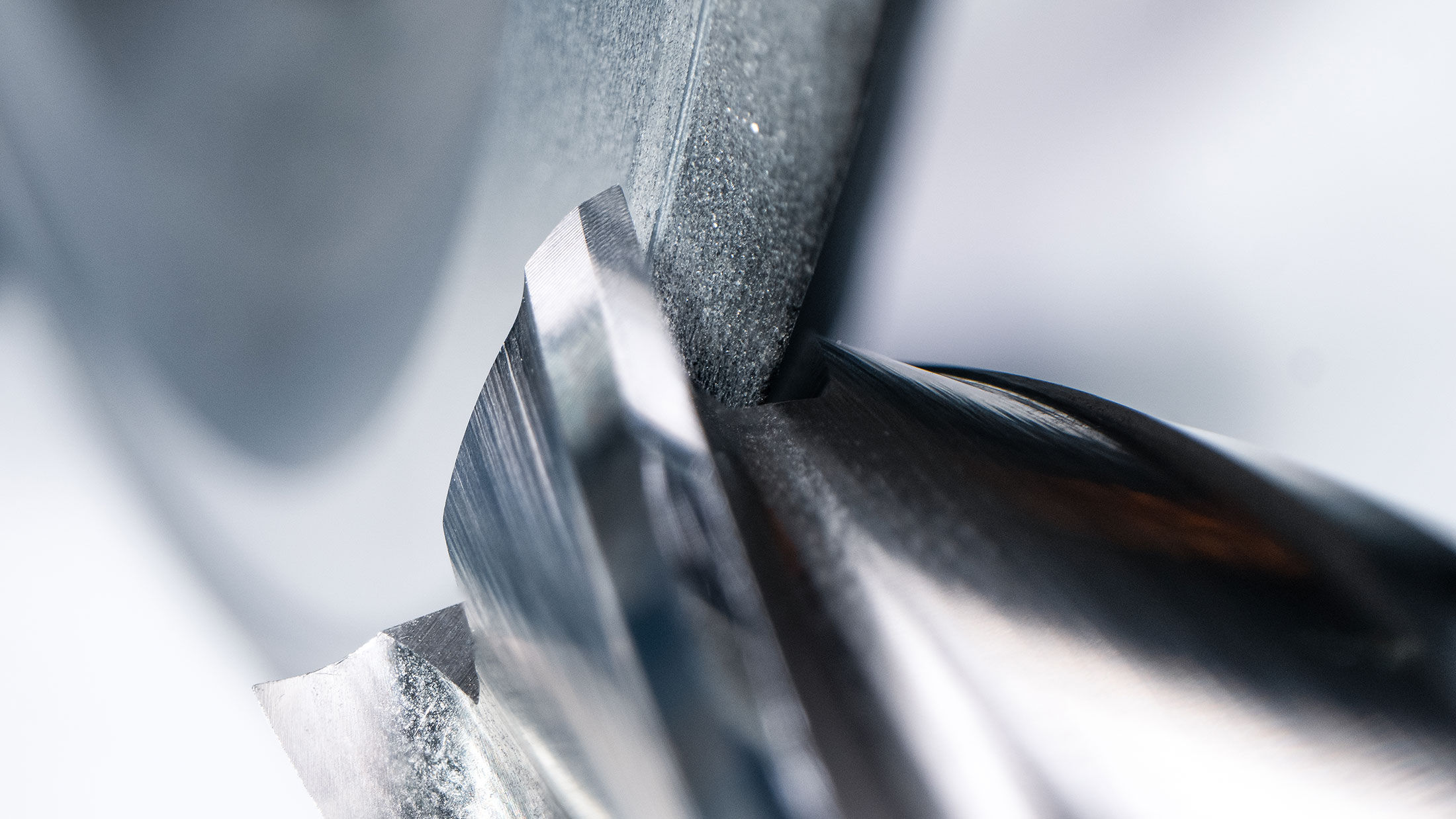

Gashing is a challenging operation, requiring the superabrasive wheel to maintain its precise profile while still removing a large amount of material. It takes the right combination of bond, grit, and abrasive quality to ensure that the tool produced is balanced, strong, and perfectly suited for its task. Mirka® Cafro gashing wheels are here to make it possible.

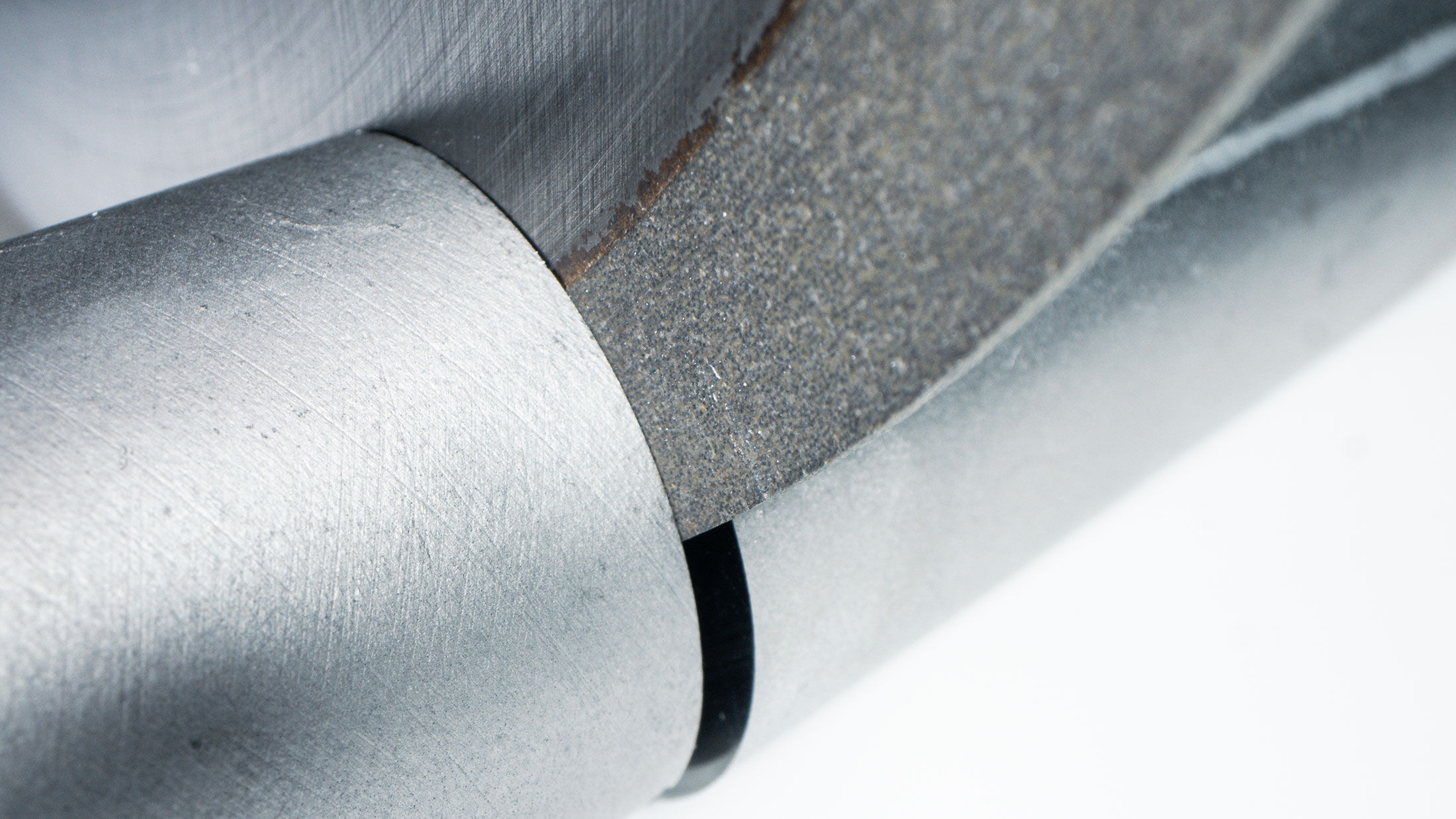

The cut-off operation is a key step in the production of round tools. It requires speed, rigidity, and thermal stability to accomplish efficiently and precisely. Mirka® Cafro cut-off wheels make quick work of this demanding operation and help you deliver a quality tool.

Please get in touch and our expert support team will answer your questions.

Mirka® Cafro´s new HP hybrid bond sets the new industry standard for high material removal