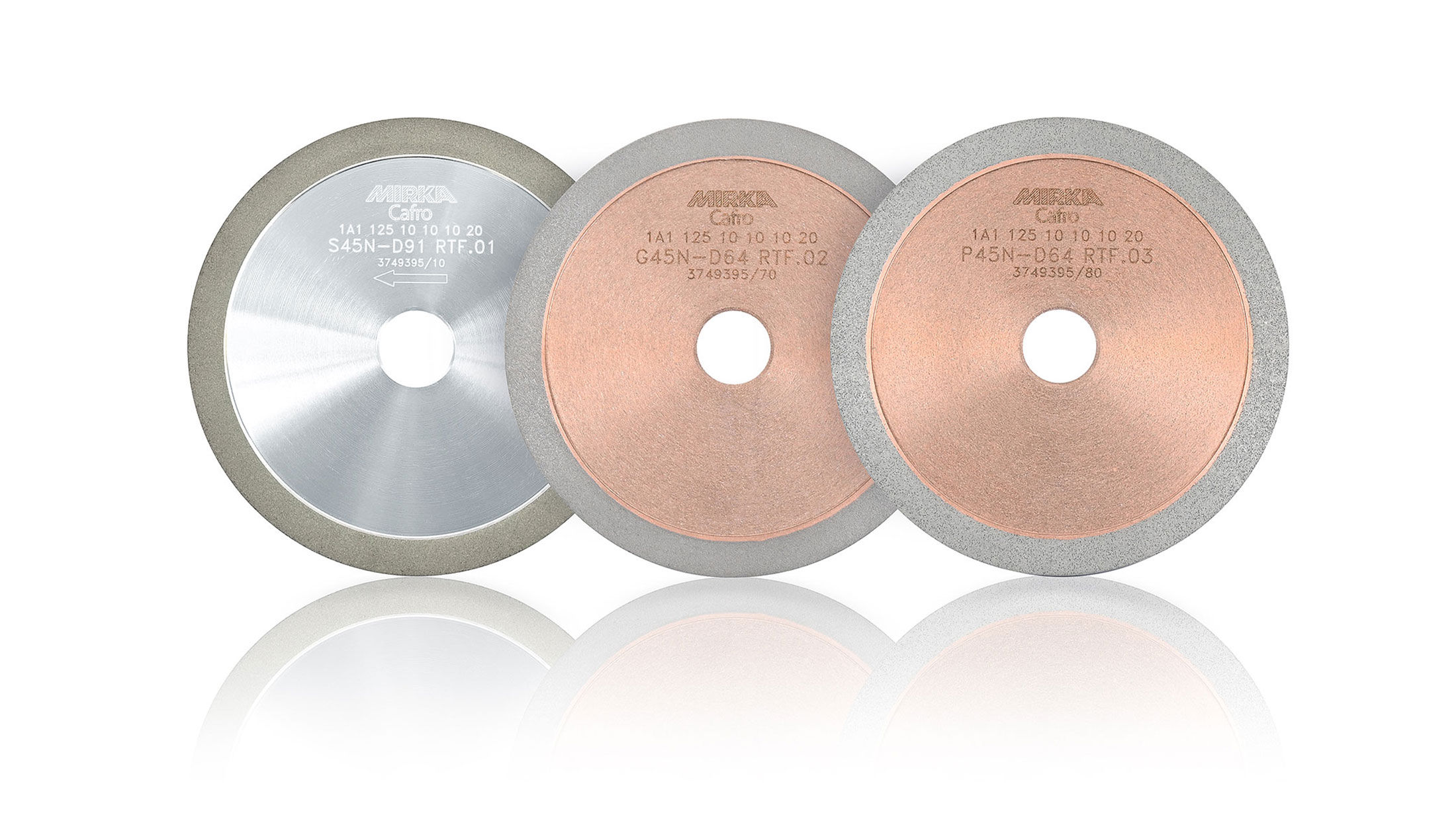

Silver• Gold•• Platinum•••

Selection Guide for Flute Grinding

Silver wheels are optimized for the efficient flute grinding of small and medium series production runs on machines with a spindle power of less than 7kW, or for small series production runs on machines with a spindle power of 7-10kW.

The Gold range is a workhorse, the quality of choice for flute grinding in medium and large series production runs. Use on machines with a sub-7kW spindle power, any series size on machines with a 7-10kW spindle power, and small to medium series production runs on machines with over 10kW of spindle power.

Platinum quality is for platinum performance of demanding tasks on high-end equipment. Our flagship Platinum wheels are what you need for the flute grinding of medium and large series on machines with a spindle power of over 10kW.

1A1 Wheels for Flute Grinding

| Wheel name | St Code | |

| SILVER | 1A1 125 10 10 10 31.75 S45N-D91 * | RTF.01U |

| GOLD | 1A1 125 10 10 10 31.75 G45N-D64 * | RTF.02U |

| PLATINUM | 1A1 125 10 10 10 31.75 P45N-D64 * | RTF.03U |

* 1A1 wheels are primarily used for endmills

U = Bore 31.75 mm

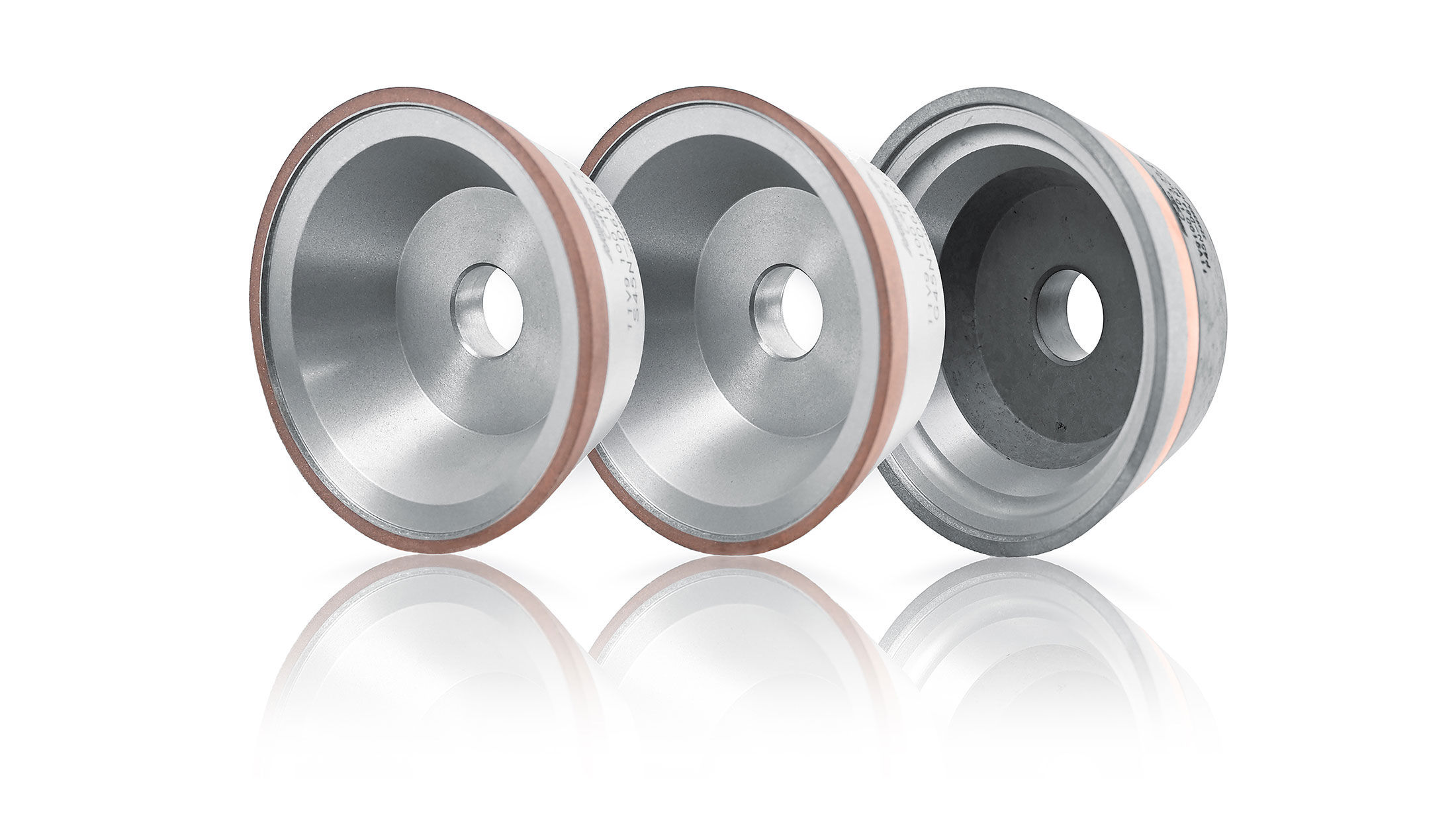

1B1V Wheels for Flute Grinding

| Wheel name | St Code | |

| SILVER | 1B1V 125 10 10 10 31.75 S45N-D91 ** | RTF.31U |

| GOLD | 1B1V 125 10 10 10 31.75 G45N-D64 * | RTF.32U |

| PLATINUM | 1B1V 125 10 10 10 31.75 P45N-D64 ** | RTF.33U |

** 1B1V wheels are primarily used for drills

U = Bore 31.75 mm

Selection Guide for Gashing and Clearance Grinding

Silver wheels are cost-effective choices for small series production with occasional dressing intervals or medium series production with frequent dressing intervals.

Gold quality wheels are ready for a wide range of series sizes. They handle small series with rare dressing intervals, medium series with occasional dressing intervals, and large series with frequent dressing intervals.

Platinum wheels are the quality of choice for the toughest grinding jobs, with a tough bond able to stand up to medium and large series sizes with long dressing intervals.

Wheels for Gashing

| Wheel name | St Code | |

| SILVER | 12V9 125 10 2 25 31.75 S45N-D64 | RTG.01U |

| GOLD | 12V9 125 10 2 25 31.75 G45N-D64 | RTG.02U |

| PLATINUM | 12V9 125 10 2 25 31.75 P45N-D64 | RTG.03U |

U = Bore 31.75 mm

Wheels for Clearance Grinding

| Wheel name | St Code | |

| SILVER | 11V9 100 10 3 35 31.75 S45N-D64 | RTC.01U |

| GOLD | 11V9 100 10 3 35 31.75 G45N-D64 | RTC.02U |

| PLATINUM | 11V9 100 10 3 35 31.75 P45N-D64 | RTC.03U |

U = Bore 31.75 mm

Wheels for Cut-Off

Gold and Platinum range cut-off wheels for dry and wet grinding.

| Wheel name | St Code | |

| DRY grinding | 1A1R 150 1,2 7 1 20 G45N-D151 | RTT.01 |

| 1A1R 200 1,2 7 1 20 G45N-D151 | RTT.02 | |

| WET grinding | 1A1R 150 1,2 7 1 20 P45N-D126 | RTT.31 |

| 1A1R 200 1,3 7 1 20 P45N-D126 | RTT.32 |

Do You Want to Know More?

Please get in touch and our expert support team will answer your questions.