2+1 years

Register Your Tool

All Mirka power tools have a standard two-year warranty. Get an additional 1 year of warranty free of charge by registering your tool within 30 days of purchase.

Keep your tools in excellent shape on myMirka where you can register, manage and order repair for your tools.

Replenish your stock, access marketing materials, view sales guides and read about upcoming product launches.

The surface finishing industry is typically following a linear economy model where the abrasive is seen as a mass-produced product that is used for a while with no recovery route available at the end of its lifetime. This is a common challenge across the whole industry.

For Mirka, boosting circularity is a key strategy to address this issue. The current linear model of the abrasives industry—where products are used briefly and then discarded—needs to evolve into a more circular system. Here we are the forerunners. By shifting to circular value chains, we can reduce waste, extend product lifetimes, and minimize the environmental footprint not only of our processes but across the entire lifecycle of the products.

Circularity is the most effective way to reduce the carbon footprint of products and manufacturing processes. By optimizing material flows, exploring more sustainable raw materials, and designing products for reuse and recyclability, Mirka is committed to ensuring that 70% of its products will be recyclable by 2035.

“The entire lifecycle will be taken into consideration already in the development phase to ensure reusability or recyclability.”

R&D Director Mats Sundell, Mirka

At Mirka, we are rethinking abrasives from the ground up, aiming for a future where every component is part of a truly circular system. We actively work to develop fully circular abrasives, where materials are continuously reused, minimizing waste and reducing the need for virgin raw materials.

Instead of relying on mined virgin grains, we are moving toward using circular grains in the future, meaning grains recovered from abrasive waste. By recycling and reprocessing the grains, we maintain their cutting performance while significantly reducing environmental impact.

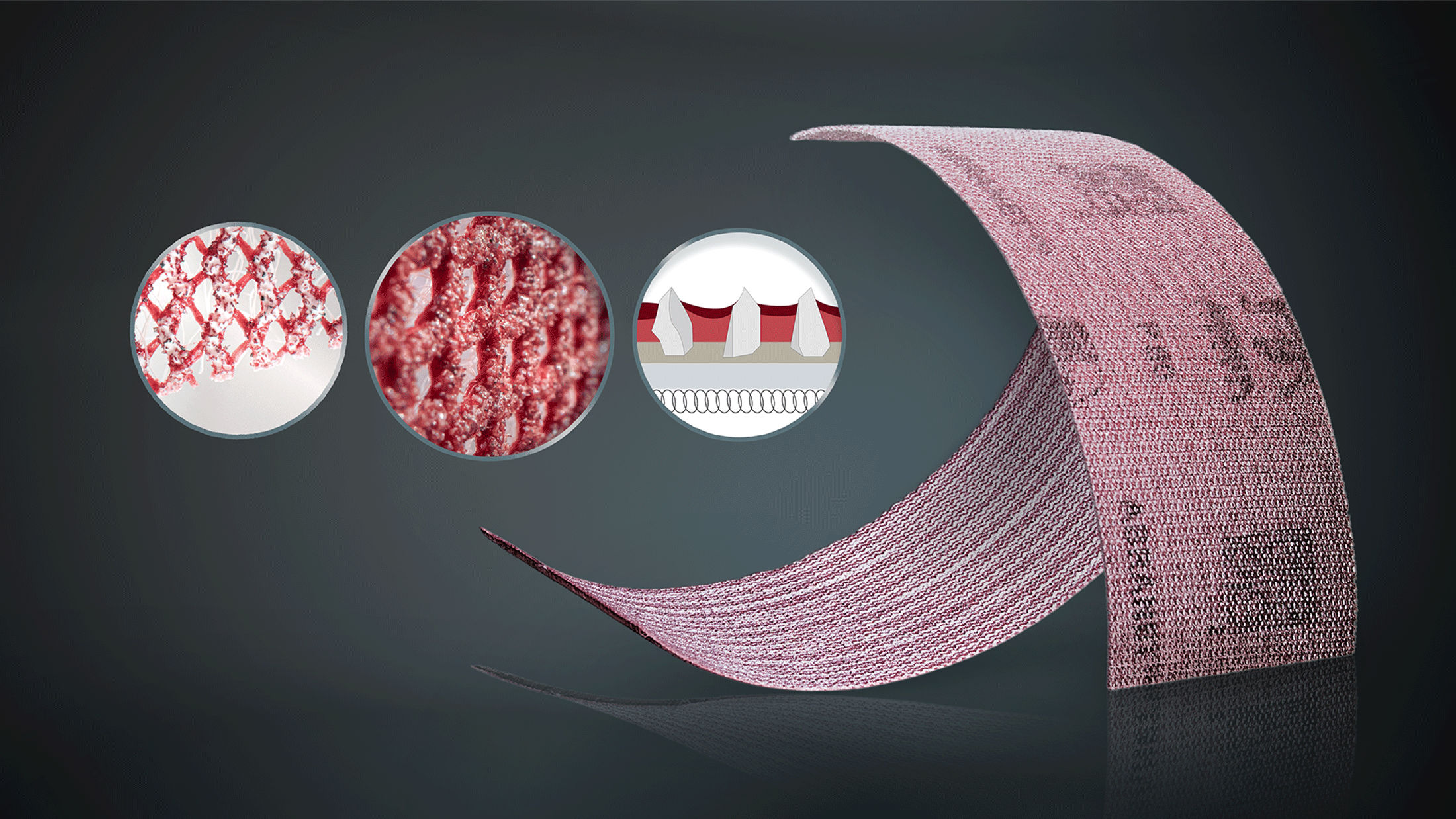

Backing materials play a crucial role in abrasives, and we are committed to use recycled fibers as textile backings, giving discarded textiles a second life and further closing the material loop.

To bind it all together, we are pioneering the development of biobased resins made from biomass, turning what was once a waste byproduct into a valuable and sustainable adhesive solution.

By integrating these innovations, we are moving towards a future where abrasives are no longer disposable but part of a continuous cycle—reducing waste, lowering carbon emissions, and making industrial processes more sustainable than ever before. This is the future of abrasives. This is circularity in action.

Mirka’s 25 million euro investment in a pioneering circular grain manufacturing plant marks a groundbreaking achievement, introducing the first truly circular concept in the global abrasives industry. By transforming abrasive waste into recycled abrasive grains for use in new products, this innovation stands as a unique example of cross-sector collaboration—demonstrating the power of collective efforts in driving sustainable innovation. The circular grain handling process enables us to move from virgin grains to utilizing used abrasive material as well as side streams currently disposed as landfill, reducing Mirka’s CO2 footprint by approximately 5000 tons. Business Finland has granted Mirka 5,89 M€ EU RRF (Recovery and Resilience Facility) funding to establish the circular grain manufacturing plant.

“Through this project Mirka will be able to lead the abrasives industry by being the first company to supply fully circular abrasives.”

Mirka’s CEO Stefan Sjöberg.

The production process of Mirka’s textile-based abrasives such as Abranet generates clean polyamide- and polyester-based textile side streams. Part of this high-quality raw material is already being recycled, and research is ongoing to further improve and expand the recycling chain. We are also exploring future raw material alternatives, such as renewable and bio-based fibers, as well as their recyclability and whether textile structural design could extend product lifespans.

Mirka is involved in several circular textile research and development projects in collaboration with industry partners, research institutions, and public organizations. These initiatives focus on advancing the circular economy in the textile industry by developing recycling solutions, promoting reuse, and creating sustainable business models for textile materials. Mirka is also a member of the European Technology Platform for the Future of Textiles and Clothing (Textile ETP) which is driving innovation and sustainability in the European textile and clothing industry.

By implementing circular design principles from the product development phase, we aim to prolong the lifetime of our products—focusing on performance, optimizing the use of raw materials, and systematically eliminating waste and harmful substances. This means designing for reuse, remanufacturing, and recycling, promoting closed-loop systems instead of linear "take-make-dispose" models.

Mirka’s circular design principles are built on the framework of the 10 R’s of Circularity.

By recycling used materials, refusing unnecessary or harmful substances, and by rethinking design, we reduce our reliance on virgin resources. Our reuse, repair, and refurbish strategies extend the lifespan of products and components, minimizing environmental impact. We actively support remanufacturing and repurposing in the society to transform old products into new solutions, further closing the loop. Through recovery, we try to ensure that materials at the end of their life are reintegrated into the production cycle rather than becoming waste.

At Mirka, we are committed to advancing sustainability in every aspect of our product development. We are continuously striving to use more sustainable raw materials, including biobased options whenever feasible, and to gain a comprehensive understanding of the composition of all materials we use. Additionally, we are dedicated to avoiding multimaterial products whenever possible, making recycling easier and more efficient. By focusing on these principles, we aim to reduce environmental impact and contribute to a circular economy.

The Mirka power tools are designed for long-lasting performance, made from high-quality, wear-resistant materials that withstand heavy use. Regular preventive maintenance is simple, helping ensure optimal performance and an extended lifespan.

If service is ever needed, our tools can be professionally maintained and repaired at authorized service centers worldwide. Designed for easy disassembly, they allow for quick part replacements instead of full disposal. Plus, we guarantee spare part availability for ten years, ensuring continued usability and minimal waste.

By combining durability, easy maintenance, and global service support, the Mirka power tools will last longer and reduce waste. Whether you're a professional or a DIY enthusiast, investing in tools built for longevity means fewer replacements, lower costs, and a reduced environmental footprint.

Our power tools are engineered and built so that anyone can easily perform preventive maintenance. Proper and regular preventive maintenance keeps your power tools performing at their best, reducing unnecessary waste and maximizing their lifespan. By taking care of your equipment, you not only save costs but also contribute to a more sustainable future by minimizing resource consumption and waste. Discover the best ways to maintain your Mirka power tools.

To extend the lifespan of the Mirka power tools and to minimize waste, we have established a well-developed global service network that provides reliable repair and maintenance support. If your power tool experiences an issue due to a material defect or workmanship error, we will repair it free of charge under the terms and conditions of the warranty.

For even longer tool life and optimal performance, you can also send in your tool for preventive maintenance, ensuring it stays in top condition. This paid service helps prevent unexpected downtime and keeps your tool running efficiently for years to come.

Select your location and find your closest professional authorized service center.

Mirka also offers an extended warranty on tools registered in our tool portal. All Mirka power tools have a standard two-year warranty. If you register your tool within 30 days of purchase, you will receive an additional one-year warranty at no extra cost. To keep the tool warranty valid and ensure optimal tool safety and function, the service of Mirka branded tools must be carried out by a Mirka authorized service center.

Maximize Lifespan, Minimize Waste, Optimize Productivity

The Premium Service Plan ensures your tool remains in optimal condition through annual check-ups, preventive maintenance, and comprehensive wear-and-tear repairs (excluding cables and backing pads). By extending your tool's lifespan and reducing unnecessary replacements, this service supports circularity, minimizes waste, and promotes a more sustainable use of resources. Additionally, our priority repair service ensures minimal downtime, allowing you to maintain productivity. In the unfortunate event of theft, we offer a one-time replacement option for your stolen tool at a 70 % discount.

By choosing the Premium Service Plan, you're not only investing in the longevity of your tools but also contributing to a more sustainable future through responsible resource management and waste reduction.

At Mirka, we are committed to fulfilling our responsibility for the end-of-life management of our power tools and batteries. We ensure compliance with applicable recycling legislation by supporting authorized waste management and contributing to the collection of waste from electrical and electronic equipment on a local level.

By working with authorized recycling organizations in each market, we help create efficient collection systems, reduce environmental impact, and promote a circular economy. Our commitment is clear, we take responsibility where it matters most: locally, in every market where our products are used.

For more information visit your local Mirka website.

Proper disposal is essential not only for power tools but also for abrasives. Learn more about how to responsibly handle your abrasives at the end of their life cycle.