2+1 years

Register Your Tool

All Mirka power tools have a standard two-year warranty. Get an additional 1 year of warranty free of charge by registering your tool within 30 days of purchase.

Keep your tools in excellent shape on myMirka where you can register, manage and order repair for your tools.

Replenish your stock, access marketing materials, view sales guides and read about upcoming product launches.

Our primary target in social responsibility is occupational health and safety (OHS). We are committed to ensuring a safe working environment for our customers, providing them with ergonomic solutions while striving to protect them from harmful substances. Internally, we are equally committed to OHS and have an ambitious target of zero workplace accidents across all our sites.

As a member of the Vision Zero Forum, a Finnish national network, Mirka actively collaborate with like-minded organizations to continuously improve occupational health and safety. The forum inspires and empowers workplaces to achieve the highest standards of safety and well-being while sharing best practices for a safer future.

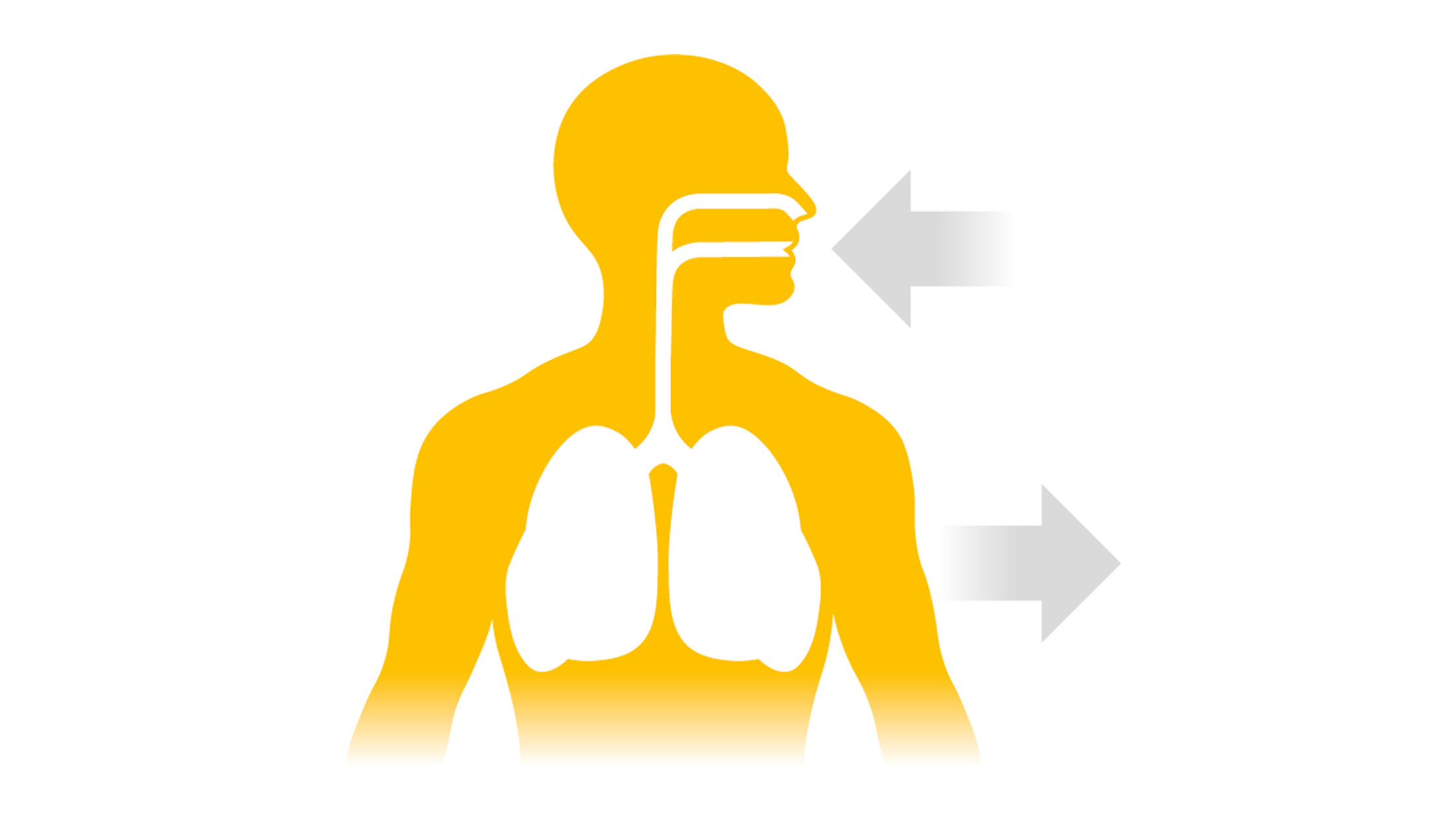

Dust is a serious problem on many levels. Dust in the workplace may also contaminate or reduce the quality of products and affect worksite productivity. Perhaps an even more important aspect of dust is that exposure to dust poses many hazards to the health and safety of millions of workers. Sanding paint and filler material creates a lot of fine dust that is easily inhaled and can cause skin, eye and upper respiratory tract irritation. The smaller the particle, the more likely it will penetrate deeply into the lungs.

Mirka is the renowned pioneer of dust-free sanding solutions, and we have succeeded in what many others have attempted to do. We are the original developer of dust-free sanding, which has since become an industry standard.

| Read more about dust-free sanding | Health Benefits of Dust-free Sanding | Efficiency Benefits of Dust-free Sanding |

Get Your Free Copy of Our Whitepaper

In this whitepaper, we consider the hazards associated with the task of sanding and the harm that can result from prolonged exposure to those hazards.

We go into the deep and explore:

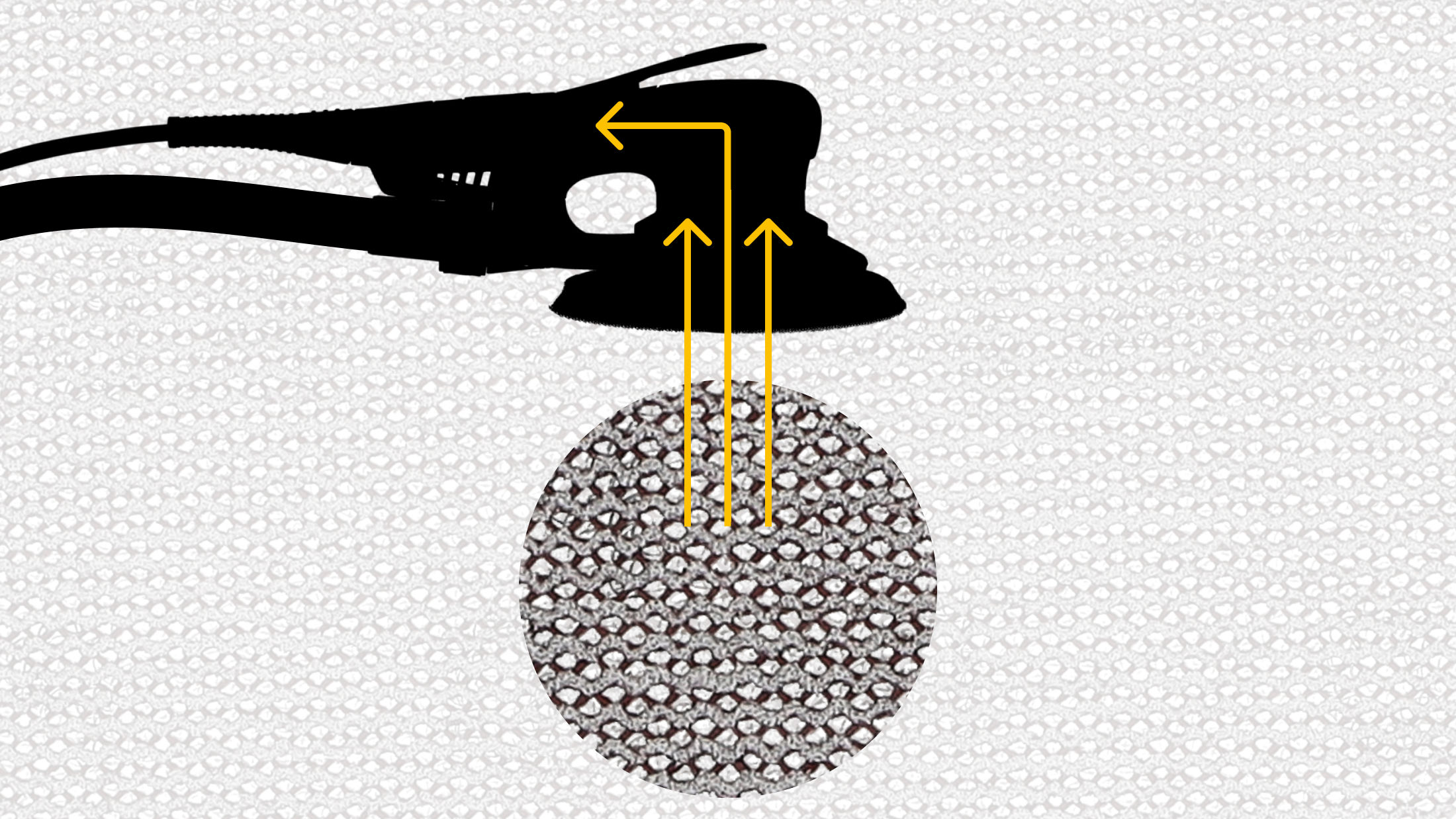

The dust-free net sanding developed by Mirka is an efficient way to minimize the amount of dust and dust related hazards in the workplace. Mirka’s dust-free solution is the combination of an ergonomic power tool and a net based Abranet sanding disc together with an efficient dust extractor.

The net structure ensures optimal dust extraction across the entire sanding disc, meaning that dust is continuously removed from the space between the abrasive and the sanded surface. Abranet in combination with Mirka power tools ensures a clean sanding which contributes to a clean and healthy working environment. Thanks to Abranet, workers’ lungs are now exposed to a much smaller amount of dust.

Daily and long-term exposure to dust is a significant occupational hazard. The number of airborne particles entering the lungs or harming skin can be strongly reduced by using an advanced and efficient dust extraction system during sanding, which also lessens the risk of a work-related disease or a dangerous exposure. Mirka dust extractors have been tested to meet the requirements of each dust class according to IEC 60335-2-69 (worldwide) and by EN 60335-2-69 (European wide) standards. Investing in a high-quality dust extraction system not only ensures compliance with occupational health and safety (OHS) regulations but also improves air quality and overall workplace efficiency.

From the very beginning, our power tools have been designed with the user in mind, prioritizing health and safety and guided by user feedback. With ergonomic designs that reduce strain, lightweight construction enhanced by brushless motor technology, low noise levels to protect against excessive noise exposure, and superior efficiency and performance, our tools create a more comfortable, and more efficient work environment.

|

“We always ask the customers what we can improve, what are their challenges” Veli-Pekka Västi, General Manager Mirka Power Tools |

Sanding often involves exposure to vibration. Excessive vibration during sanding can lead to issues like hand-arm vibration syndrome (HAVS), which may cause numbness, tingling, or reduced grip strength over time. Prolonged exposure to these vibrations can also contribute to musculoskeletal strain, fatigue, and discomfort. To mitigate these risks, it’s important for users to take regular breaks, and choose sanding equipment designed to minimize vibration. Proper posture and grip techniques also help reduce the impact on the user’s hands and arms.

In addition to our ergonomically designed power tools, we have developed the myMirka app for vibration tracking to further protect users from excessive vibration exposure. The myMirka app helps to monitor the amount of vibration users are exposed to when operating a Mirka power tool. By measuring vibration levels over time, the app provides insights into whether exposure is within safe limits and helps to identify when users should take breaks. This can improve workplace safety, prevent long-term health issues and sick leaves, and ensure compliance with occupational health and safety standards.

Personal protective equipment (PPE) is worn to reduce the risk of exposure to workplace hazards that can lead to serious injuries or illnesses. Mirka have always been dedicated to protecting its users’ health and safety. That’s why we’ve expanded our core range of premium power tools and abrasives to include a full line of personal protective equipment, offering a holistic safety solution. Mirka’s personal protection equipment range covers everything from protective overalls, safety eyewear to hand protection as well as face and breathing protection.

Advanced robotic systems for the automation of tasks have entered many industrial sectors during the past years. At Mirka we see that sanding automation brings numerous OHS benefits.

Mirka’s robotic sanding solutions are designed for seamless integration with industrial automation, improving precision and ensuring a safer work environment.