2+1 years

Register Your Tool

All Mirka power tools have a standard two-year warranty. Get an additional 1 year of warranty free of charge by registering your tool within 30 days of purchase.

Keep your tools in excellent shape on myMirka where you can register, manage and order repair for your tools.

Replenish your stock, access marketing materials, view sales guides and read about upcoming product launches.

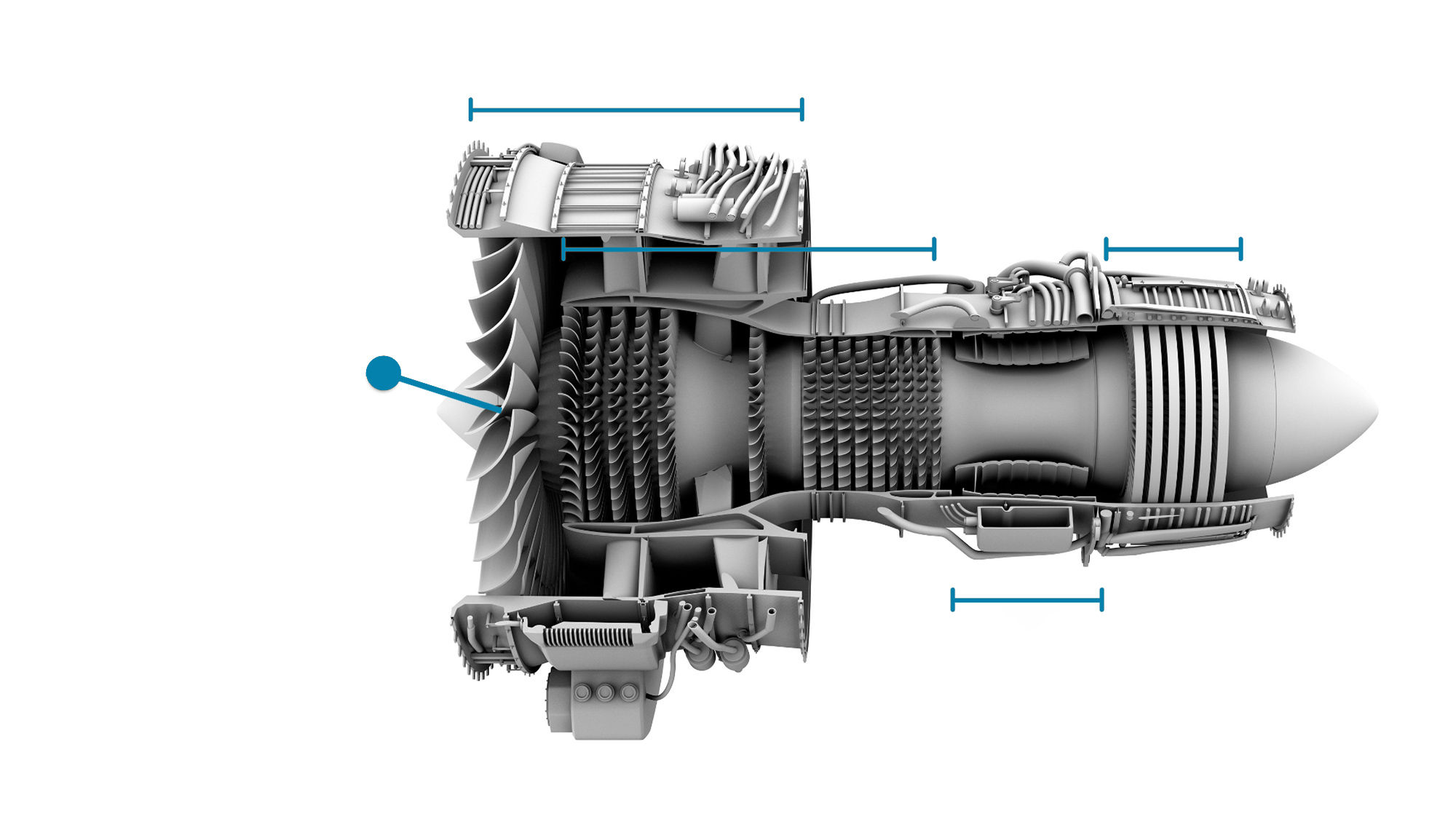

Implement measurement and tools depending on the task at hand

Mirka’s technology can increase the adaptibility of the process by adding optional automatic edge break measurement. Various tools can also be implemented, including abrasive brushes, abrasive discs, CBN grinding wheels and carbide files.

Suitable for wet or dry process

Mirka uses a compact S-series cell for turbine blade finishing, suitable for either wet or dry process environment depending on material requirements.

The resulting uniform surface quality minimizes process waste and scrap rate, with increased yearly production capacity. As an added bonus, the automated process reduces strain on the operator.

Precision and flexibility

The powerful and compact S-series platform utilizes well-proven technologies, increasing total tool-on-contact time. It is perfect for handling and finishing complicated shapes with the highest precision, quality and flexibility.

The compact design of the cell saves floor space and it can be integrated to an FMS-System. It is easy to set up and operate, and it is compatible with toolpath programming with any five-axis CAD/CAM environment.