2+1 years

Register Your Tool

All Mirka power tools have a standard two-year warranty. Get an additional 1 year of warranty free of charge by registering your tool within 30 days of purchase.

Keep your tools in excellent shape on myMirka where you can register, manage and order repair for your tools.

Replenish your stock, access marketing materials, view sales guides and read about upcoming product launches.

Why choose Mirka® Industrial Automation?

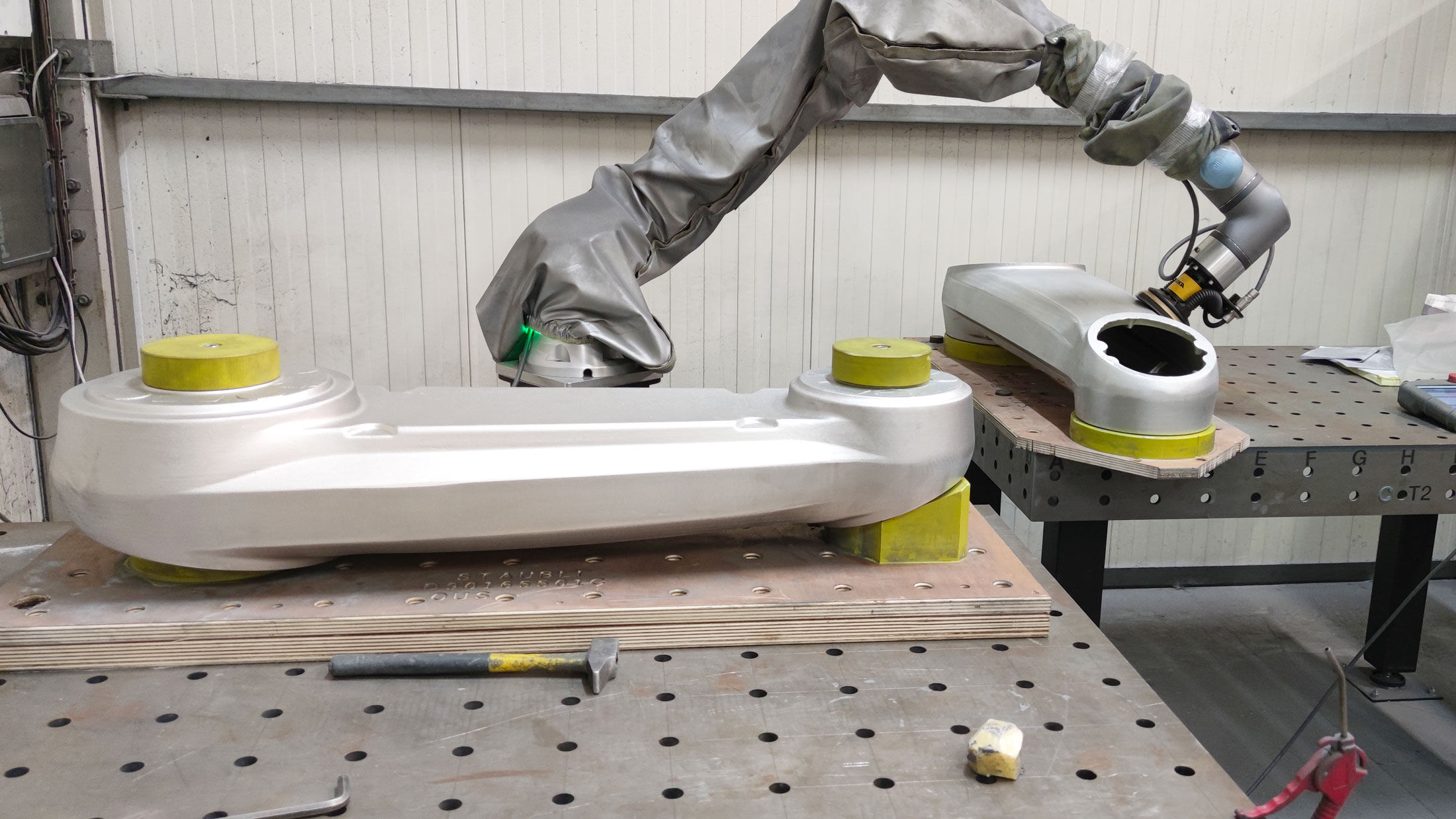

With over 80 years in surface finishing, Mirka offers everything you need to optimize robotic sanding, polishing, and grinding—no matter the shape, size, or complexity of your surfaces. From specialized tools and abrasives to expert support, we’re your one-stop shop for automation.

Our compact, versatile robotic tools handle everything from flat panels to curved, contoured, and irregular forms. Compatible with most industrial robots and cobots, they excel in tasks like wet sanding and hazardous material processing.

Partnering with system integrators and end users, we deliver turnkey solutions that seamlessly integrate into your processes, maximizing efficiency and ensuring consistent, high-quality results every time.

Upgrade your current system or get a complete solution

Replacing manual sanding, grinding, deburring, and polishing work with robotics increases production capacity. Mirka’s robotic surface finishing solutions enable you to move from partial process optimization to end-to-end automation.

The main benefits of automation include consistent results and bionic precision. With Mirka's industrial automation solutions, you get exceptional results day after day, year after year.

Most work-related injuries are avoidable. By automating processes that are physically demanding or involve dust, welding flames, or other dangerous operations, you can create a safer workplace with fewer injuries and lost time.

Volkswagen

The Wolfsburg Volkswagen plant in Germany is one of the biggest factories in the world. It's also one of many modern production sites that utilize Mirka's automation solutions.

Volkswagen has really put Mirka's robotic AIROS sanders to the test and relied heavily on them since 2018 with great success.

INCOsystems

When INCOsystems sought to revolutionize their production processes, they chose Mirka's robotic sanding solutions. The result? A partnership that delivered beyond expectations.

– INCOsystems management team

Aquaestil

The Croatian bathroom equipment manufacturer Aquaestil improved its productivity and operational accuracy with Mirka's AIROS sanders and automatic disc changer units.

– Aquaestil

Loire Fonderie

One of automation's indisputable advantages is consistency. This is one of the reasons why French precision casting company Loire Fonderie chose to invest in robots and Mirka's AIROS sanders.

– Loire Fonderie

Furch Guitars

A symphony of machine sounds welcomes you at Furch's guitar factory in the Czech Republic. Mirka's automated sanding heads contribute to this efficient, finely-tuned harmony.

– Furch Guitars

ISYCOD

The French company ISYCOD specializes in designing and supporting robotic systems for various industries. When tasked with delivering a solution for an automated sanding line, they chose to pair UR robots with Mirka's AIROS sanders.

– ISYCOD

AeroSpline

In 2019, AeroSpline, a French cobot integrator, set out to develop an automated mobile sanding unit. They contacted Mirka and initiated a collaboration. The partnership was a great success and AeroSpline now has several mobile sanding units equipped with Mirka's sanding tools, abrasives, dust extraction system and AutoChanger.

– AeroSpline

Tools

AIROS, AIROP, AIOS and AIRP sanders and polishers, belt grinders, spindle motors.

Robotic Appliances

Force control and compliance units, motor drive cabinets, disc changers, belt changers and toolholders.

Abrasives and Compounds

Optimal abrasives, belts, polishing fluids, etc. for your applications.

Software

Tool Time Manager, MillControl UI, and other plugins and apps for various robots, tools and automatisation purposes.

Automatic abrasive changes for perfect sanding results

Designed for robotic dry sanding, the Mirka® AutoChanger ensures precise, repeatable abrasive disc changes without interruptions.

Suitable for dry sanding with both net and multihole abrasives, a correctly set-up Mirka Autochanger system provides an industrial sanding process with perfect sanding results, time after time.

Get up to speed faster with Mirka’s robotic solutions tailored for leading brands like ABB, Universal Robots (UR), and Fanuc CRX models. We provide installation kits that include the Mirka tool, motor drive cabinet, cabling, and the required adaptor flange for each robot type. A Mirka abrasive sample kit is also included.

Whether you're working with ABB (see Mirka solutions on RoboticsOne), UR, or Fanuc robots, Mirka’s plugins and software solutions ensure seamless integration and optimized performance.

If you want to receive CAD files, access software or more information about the General Conditions – Orgalime, please contact us by filling out this form.

Brochure: Mirka® Robotic Solutions

You can find manuals here:

Payment and delivery terms as stated in the final offer, other terms: According to Orgalime S2012 General Conditions for the Supply of Mechanical, Electrical and Electronic Products.